Xinxiang Changsheng Refrigeration Equipment Co., Ltd.

is an experienced and professional Production evaporator& condenser factory supplier in China. Our team stay focused on wire on tube evaporator& condenser,for over 10 years.

Our Product

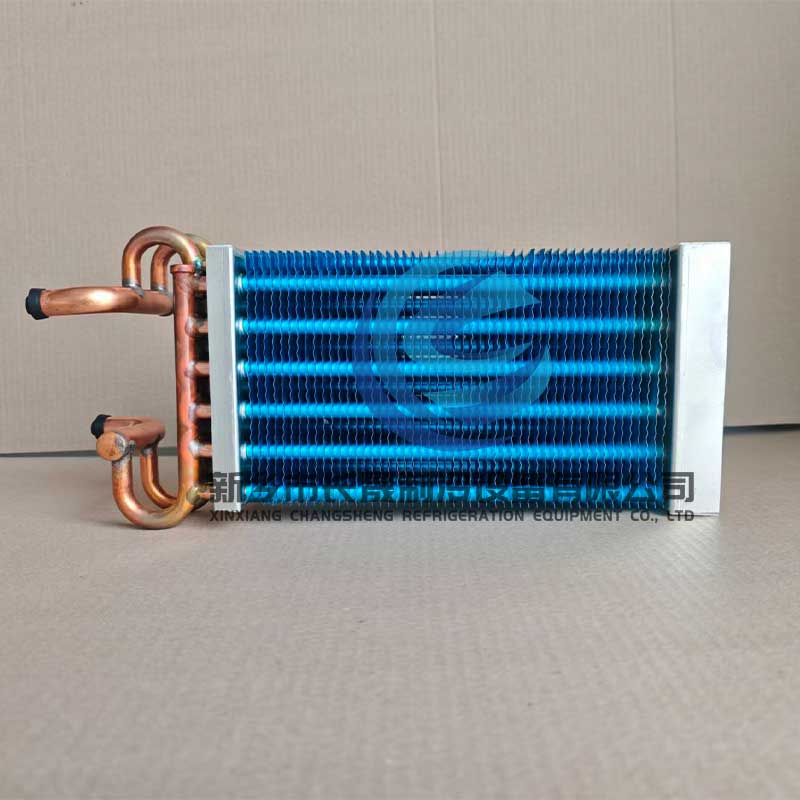

The main products of our company are aluminum tube fin evaporator, copper tube fin evaporator, wire on tube evaporator& condenser,micro-channel heater exchanger,tube on plate evaporator. Also all products raw materials ,such as Aluminum coil/foil/sheet,Aluminum tube, copper tube,steel wire, copper-aluminum pipe joints ,accumulator,freezer fittings and air conditioner connecting pipe fittings, filters and related products.

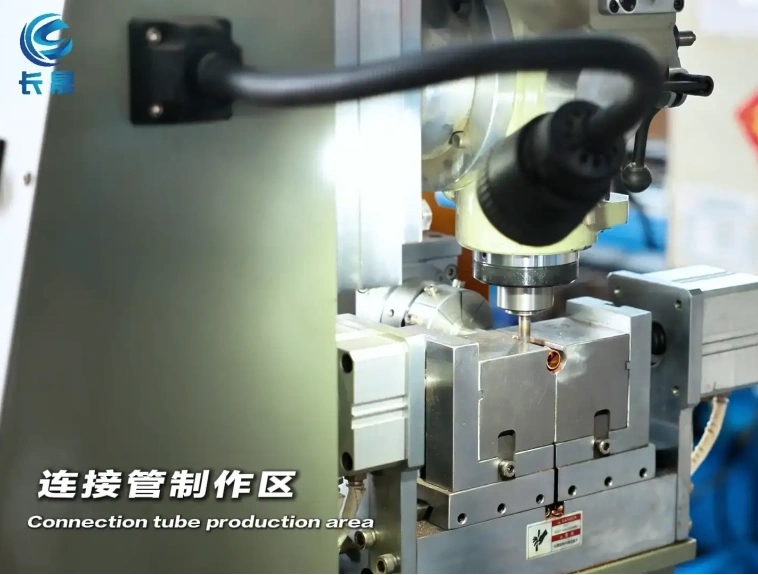

VIDEO INTRODUCTION

Factory Showcase

if you have any enquiry about quotation or cooperation, please feel free to email us at info@cs-refrigeration.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.

Our address

Xinxiang Economic Development Zone, Henan, China

Phone Number

8618337312531

info@cs-refrigeration.com