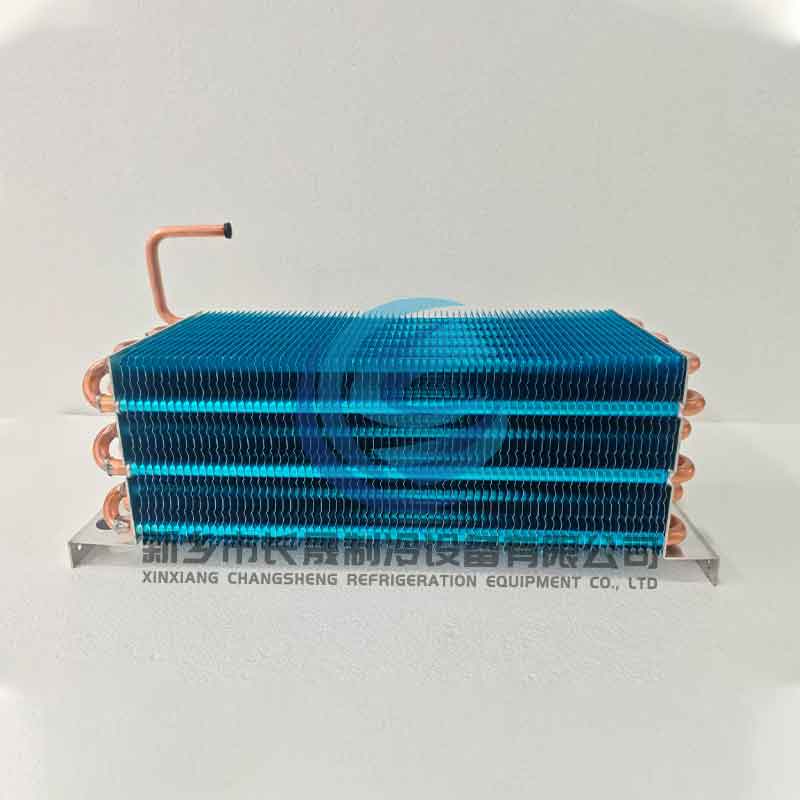

Plate on Tube Evaporator with Aluminum

**Plate on Tube Evaporator with Aluminum (aluminum tube plate evaporator)** is a heat exchanger that combines aluminum plates and copper tubes (or other metal tubes), which is often used in refrige...

Products Description

**Plate on Tube Evaporator with Aluminum (aluminum tube plate evaporator)** is a heat exchanger that combines aluminum plates and copper tubes (or other metal tubes), which is often used in refrigeration systems.

Ⅰ. Definition and structure

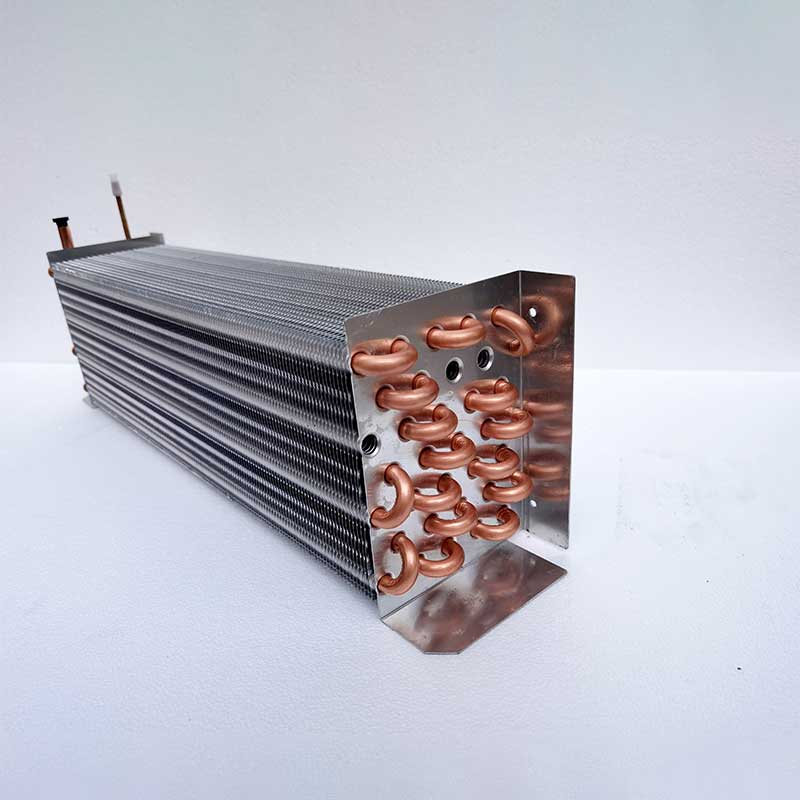

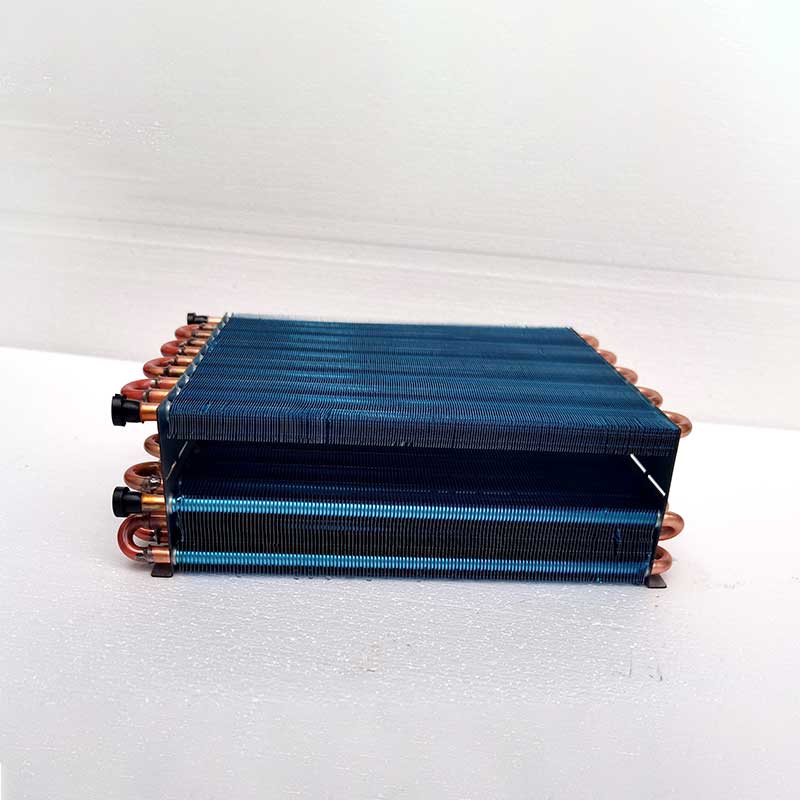

The aluminum tube plate evaporator consists of aluminum plates and metal tubes (such as copper tubes). The aluminum plate serves as a heat transfer medium, while the metal tube is embedded between the aluminum plates to form the core of the heat exchange. The refrigerant flows in the tube and exchanges heat with the aluminum plate through the tube wall, thereby absorbing or releasing heat.

Ⅱ. Features and advantages

1. **Efficient heat exchange**: Aluminum materials have good thermal conductivity, can quickly transfer heat, and improve heat exchange efficiency.

2. **Strong corrosion resistance**: Aluminum materials have good corrosion resistance to a variety of chemicals and can maintain stable performance in harsh environments.

3. **Lightweight and high strength**: Aluminum materials have low density and light weight, but high strength and can withstand certain mechanical pressure.

4. **Easy to process and maintain**: Aluminum materials are easy to cut, bend and weld, and can be processed into various shapes and sizes. At the same time, the aluminum evaporator has a compact structure and is easy to disassemble and clean.

III. Working principle

The working principle of the aluminum tube-sheet evaporator is based on the principle of heat exchange. When the refrigerant flows in the tube, it absorbs or releases heat, which is transferred to the aluminum plate through the tube wall. The aluminum plate then transfers the heat to the surrounding air or water and other media, thereby achieving the purpose of cooling or heating.

IV. Application scenarios

Aluminum tube-sheet evaporators are widely used in various refrigeration systems, such as refrigerated containers, cold chain logistics vehicles, refrigeration and air-conditioning equipment, etc. Especially in refrigeration occasions that require high efficiency, corrosion resistance, light weight and high strength, aluminum tube-sheet evaporators have significant advantages.

V. Precautions

1. **Avoid excessive pressure**: During use, avoid applying excessive pressure to the evaporator to avoid damaging its structure.

2. **Prevent freezing**: When used in a low temperature environment, the evaporator should be prevented from freezing. Insulation measures or heating devices can be taken to prevent freezing.

3. **Correct installation**: The installation of the evaporator should comply with relevant standards and specifications to ensure its stability and safety.

In summary, the aluminum tube-sheet evaporator has the characteristics of efficient heat exchange, strong corrosion resistance, light weight and high strength, and easy processing and maintenance. It has broad application prospects and development potential in refrigeration systems. Regular maintenance and other measures can ensure the normal operation of the evaporator and extend its service life.

Send Inquiry

You Might Also Like

-

Custom copper tube fin evaporator

-

Coca-Cola Beverage Cabinet KSV Series Refrigerator Freezer Evaporator

-

Evaporator Refrigeration plate Freezer refrigerator Freezer Refrigerated display cabinet Freezer Copper tube fin air-cooled condenser

-

Freezer display cabinet vertical cabinet cake cabinet pastry cabinet evaporator condenser pure copper tube

-

Air-cooled evaporator condenser Display cabinet cake cabinet refrigerator freezer refrigerator copper tube aluminum fin evaporator

-

Roll Bond Aluminum Evaporator