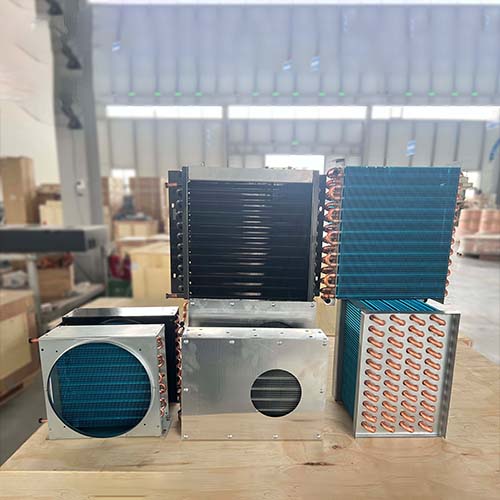

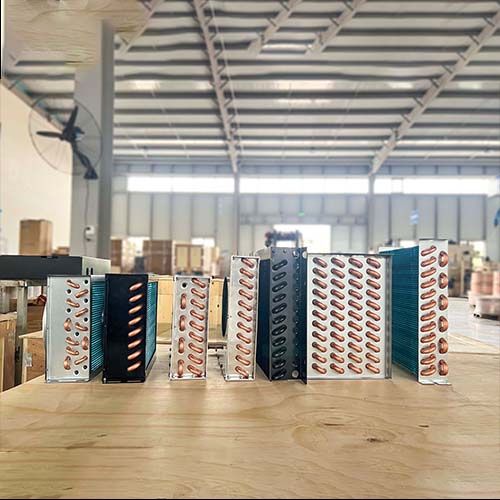

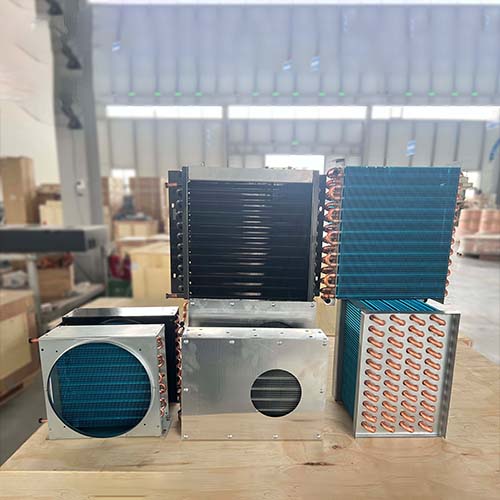

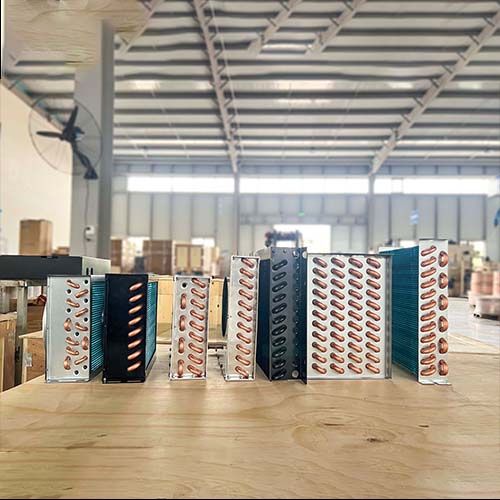

Fin condenser

The copper tube aluminum fin condenser is a high-efficiency heat exchange device composed of copper tubes and aluminum fins. It uses its high thermal conductivity and corrosion resistance to transmit refrigerant. The aluminum fins enhance heat dissipation by expanding the surface area, condensing the gaseous refrigerant into liquid and releasing latent heat. It has the advantages of high efficiency heat exchange, light weight and low cost, and is the core of refrigeration.

Products Description

1. Copper tube: As a circulation pipe for heat transfer media (such as refrigerants), copper becomes the core heat transfer material due to its high thermal conductivity (thermal conductivity coefficient is about 400 W/m·K) and corrosion resistance.

2. Aluminum fins: Tightly wrapped around the outer wall of the copper tube through mechanical expansion or welding process to form a dense fin array. Aluminum significantly increases the heat dissipation surface area and improves the overall heat exchange efficiency due to its light weight (density is only 30% of copper) and low cost.

Function: In the refrigeration/heat pump system, the high-temperature and high-pressure gaseous refrigerant is condensed into liquid through heat exchange with the ambient air, releasing latent heat (such as the condensation latent heat of R410A refrigerant is about 200-250 kJ/kg), completing the key link of the refrigeration cycle

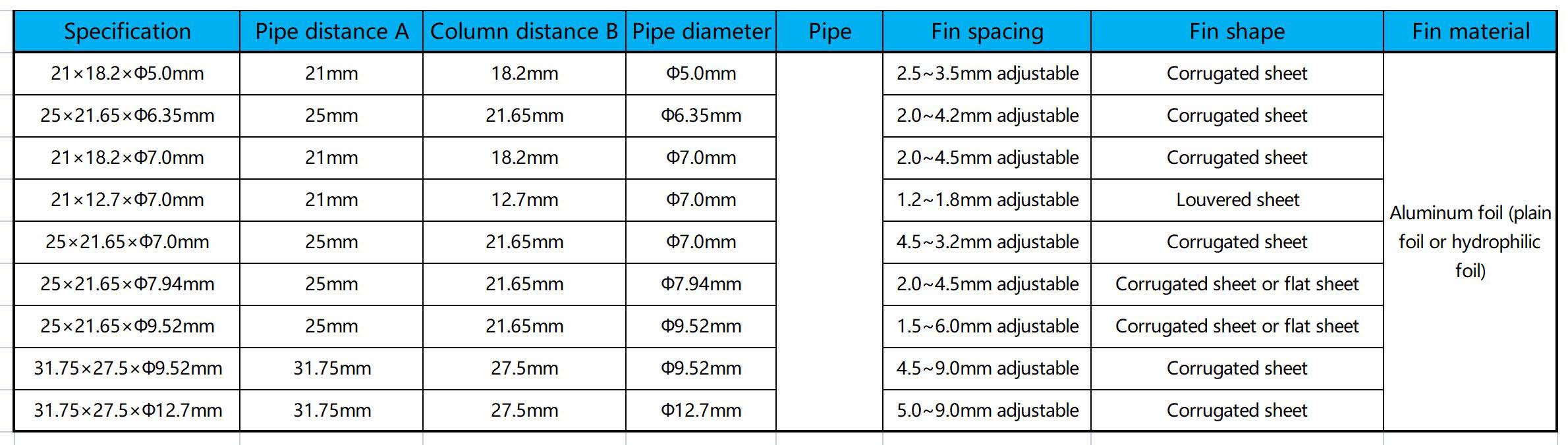

3. Structure and materials – Base tube: Usually a copper tube with a diameter of Φ5~15.88mm and a wall thickness of 0.32~0.41mm. Some of them adopt an internal fin design to enhance the heat transfer in the tube. – Fin: The thickness of the aluminum foil is 0.12mm, and a corrugated or serrated surface is formed by stamping to optimize the airflow disturbance. – Connection process: The copper elbow and the piping adopt a Φ7~8mm specification to ensure the sealing and pressure bearing capacity (such as the pressure test up to 30MPa).

4. Manufacturing process – Surface treatment: The copper tube is dipped in varnish or electrophoretic paint, and the aluminum fin is anodized to improve corrosion resistance. – Internal cleanliness: High temperature vacuum drying process ensures that the refrigerant flow path is free of impurities and passes leak detection.

VIDEO INTRODUCTION

FAQ

Q1: How can I make an order?

A1: Inquiry → Quotation → Order → Payment → Delivery → Deal → Feedback

Q2: What is your terms of payment?

A2: T/T 30% as deposit, and 70% before delivery. We ll show you the photos of the products and packages before you pay the balance.

Q3: What is your terms of delivery?

A3:Convenience by Western Union/Money Gram/Trade Assurance/Paypal/T/T etc.

Q4: How about your delivery time?

A4: Generally, it will take 15 to 40 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5: Can you produce according to the samples?

A5: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6: What is your sample policy?

A6: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7: Do you test all your goods before delivery?

A7: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A8: 1. We keep good quality and competitive price to ensure our customers benefit ; 2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Q9: What is your Minimum Order Quality?

A9: Different products have different MOQ,but we can sell you even one piece if we have stock the model of you need.

Send Inquiry

You Might Also Like

-

Precision Copper Tube Fin Evaporators for Food Processing and Cold Storage

-

Copper tube aluminum fin condenser: a core component of commercial display case refrigeration systems.

-

High-efficiency and energy-saving copper tube aluminum fin evaporator, core component of commercial display case and beer cabinet refrigeration system.

-

Long-Lasting Finned heat exchangers for Dehumidification and Drying Systems

-

OEM/ODM Copper-Aluminum Fin Heat Exchangers for Diverse Industrial Applications

-

Custom Industrial Copper Tube Fin Heat Exchangers for Refrigeration & Cooling Plants