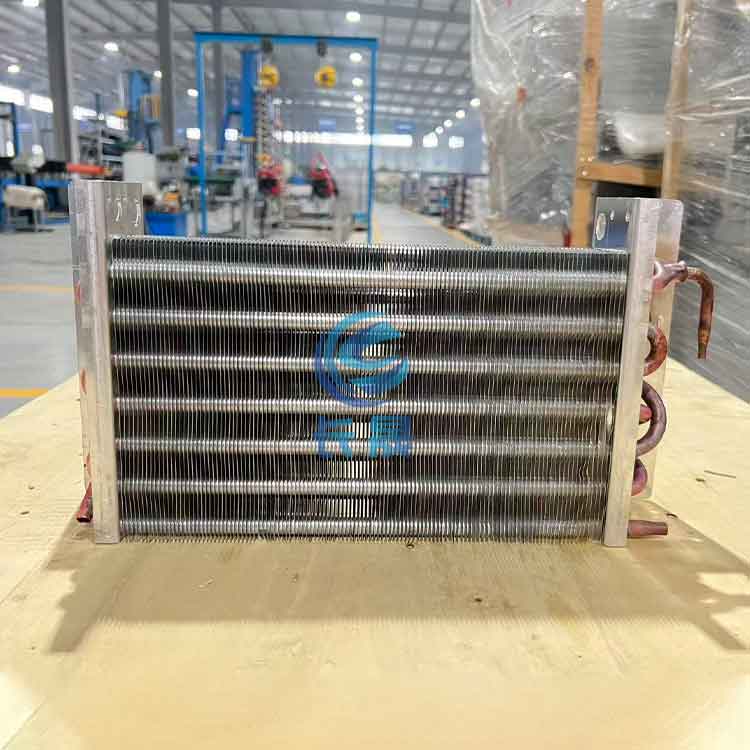

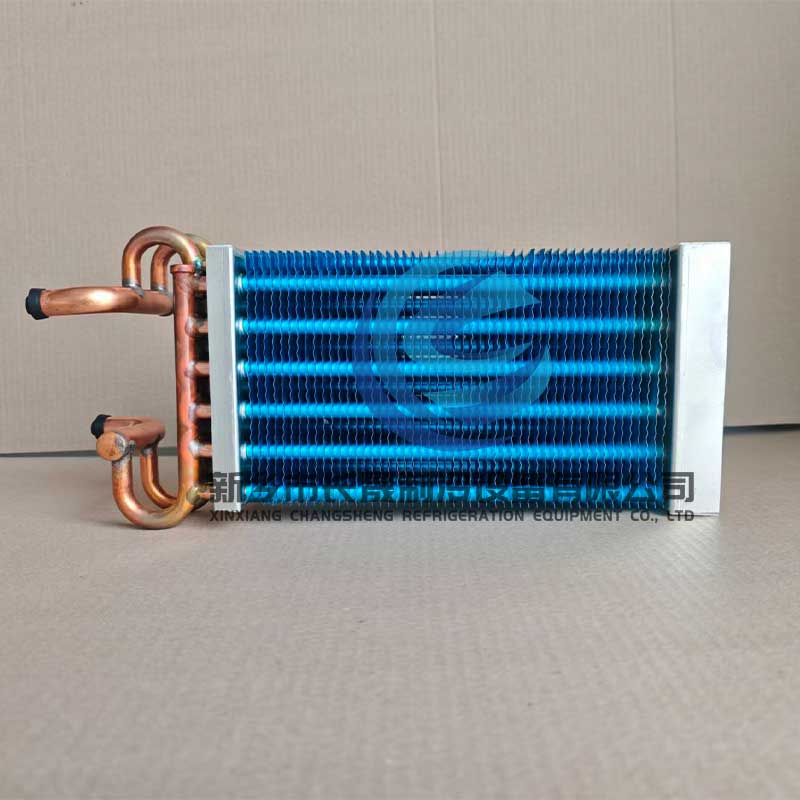

Enhanced surface aluminum finned evaporator coil

Enhanced surface aluminum finned evaporator coils used in double-door direct-cooling refrigerators, freezers, air coolers, and air conditioning equipment.

Products Description

1. Core Component Analysis

The first part of the title, “Enhanced surface aluminum finned evaporator coils,” indicates the product’s technical essence.

“Evaporator coils” are the heart of the refrigeration system, responsible for absorbing heat. They typically consist of copper refrigerant flow channels and tightly fitted aluminum fins. The core function of the aluminum fins is to significantly expand the heat exchange area in contact with the air, thereby efficiently transferring the cooling energy generated by refrigerant evaporation within the channels to the air.

“Enhanced surface aluminum fins” are the product’s key technological innovation and selling point. Here, “enhanced surface” specifically refers to physical or chemical optimization treatments applied to standard aluminum fins. The two most common methods are:

Corrugated or slit design: By stamping the fins into a corrugated shape or creating slits, the flowing air can be effectively disturbed, disrupting the stable boundary layer that hinders heat exchange, enhancing turbulence, and thus directly improving heat exchange efficiency.

2. Wide Range of Applications

Double-Door Direct-Cooling Refrigerators: In these refrigerators, the coil typically serves as the primary cold source for the refrigerator compartment. Its design emphasizes close integration with the internal space, uniform heat exchange, and corrosion resistance to humid environments.

Freezers: When used in freezers, the coil needs to operate stably for extended periods at temperatures as low as -18°C and below, and withstand severe frost buildup. Therefore, its design must prioritize the low-temperature toughness of materials, appropriate fin spacing to delay frost blockage, and efficient defrosting compatibility.

Air Coolers: These are forced-ventilation air coolers used in environments such as cold storage and industrial processes. In these high-load, potentially harsh environments, the coil requires a robust structure, enhanced corrosion resistance (e.g., using coatings or special materials), and a design to accommodate high airflow and heat exchange demands.

Air Conditioning Equipment: As the core of the indoor unit of a residential or commercial air conditioner, the coil is responsible for cooling and dehumidifying the room air. In this scenario, the core performance indicators are extremely high energy efficiency ratio, low operating wind resistance and noise, compact and lightweight structure, and excellent drainage capacity to ensure dehumidification effect and prevent water from blowing away.

Application scenario demonstration

Core Functions and Roles

Evaporator: The “heat-absorbing device” in the refrigeration system. Its core function is to absorb heat inside the cabinet, thereby lowering the internal temperature and achieving a cooling effect. You can think of it as the “cold energy producer” in the refrigeration cycle.

Condenser: The “heat-releasing device” in the refrigeration system. Its core function is to release the heat carried by the high-temperature, high-pressure refrigerant gas discharged from the compressor to the external environment. You can think of it as the “heat transporter” in the refrigeration cycle.

More product displays

Our Value Commitment

As a professional evaporator/condenser manufacturer, we are committed to providing:

High performance: Strict design and process control to ensure that the product achieves the best heat exchange efficiency.

High reliability: Selection of high-quality materials, advanced manufacturing processes and strict quality control to ensure long-term stable operation of the product.

Customization capability: Flexible design and production according to customer specific needs (size, heat exchange capacity, interface, refrigerant type, etc.).

VIDEO INTRODUCTION

FAQ

Q1: How can I make an order?

A1: Inquiry → Quotation → Order → Payment → Delivery → Deal → Feedback

Q2: What is your terms of payment?

A2: T/T 30% as deposit, and 70% before delivery. We ll show you the photos of the products and packages before you pay the balance.

Q3: What is your terms of delivery?

A3:Convenience by Western Union/Money Gram/Trade Assurance/Paypal/T/T etc.

Q4: How about your delivery time?

A4: Generally, it will take 15 to 40 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5: Can you produce according to the samples?

A5: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6: What is your sample policy?

A6: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7: Do you test all your goods before delivery?

A7: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A8: 1. We keep good quality and competitive price to ensure our customers benefit ; 2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Q9: What is your Minimum Order Quality?

A9: Different products have different MOQ,but we can sell you even one piece if we have stock the model of you need.

Send Inquiry

You Might Also Like

-

Precision Copper Tube Fin Evaporators for Food Processing and Cold Storage

-

High-efficiency and energy-saving copper tube aluminum fin evaporator, core component of commercial display case and beer cabinet refrigeration system.

-

Long-Lasting Finned heat exchangers for Dehumidification and Drying Systems

-

High-Efficiency Copper Tube Aluminum Fin Condensers & Evaporators for HVAC Systems

-

Internally threaded copper tube aluminum foil finned condenser,

-

Customized evaporator, condenser, and coil; high-efficiency refrigeration; copper tube and aluminum fin heat exchanger.