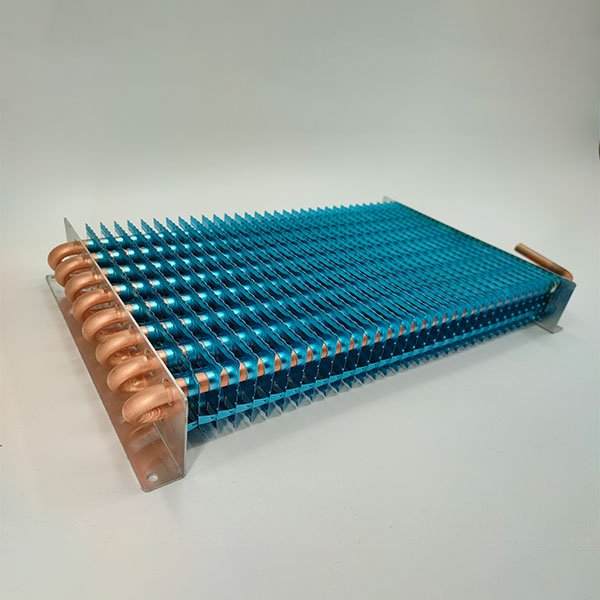

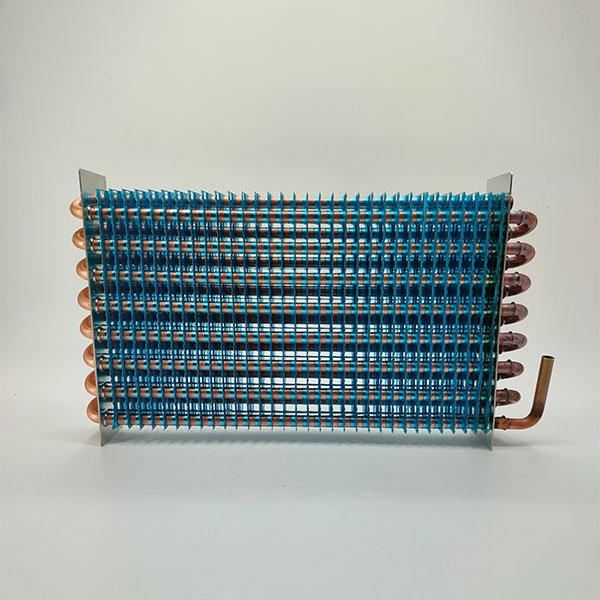

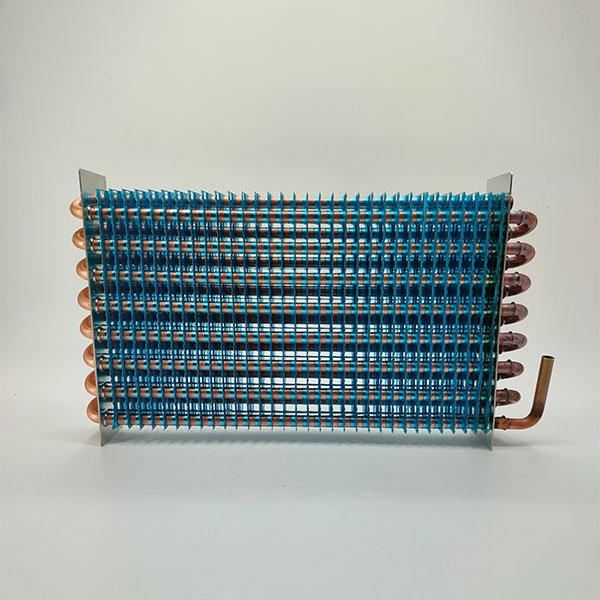

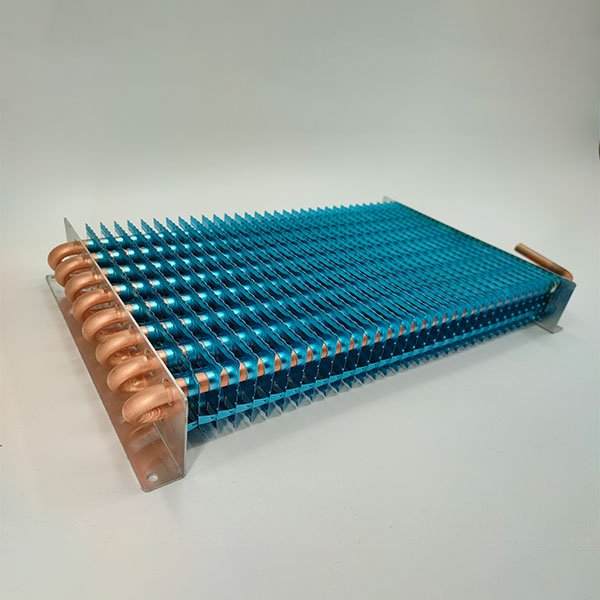

Display cabinet evaporator

The copper tube fin evaporator is a highly efficient heat exchange device. Its core structure is made of copper tube (base tube) and aluminum fin (extended surface) tightly combined through mechanical expansion or hydraulic expansion process. It significantly improves the heat exchange efficiency by increasing the heat transfer area (fin surface area + base tube surface area).

Products Description

1. Structure and Materials

Base pipe: usually a copper pipe with a diameter of 5~15.88mm and a wall thickness of 0.28~0.41mm. Some parts use internal rib design to enhance heat transfer inside the pipe.

Fin: Aluminum foil thickness of 0.12mm, formed into a corrugated or serrated surface through stamping to optimize airflow disturbance.

– Connection process: The copper elbow and piping adopt a specification of Φ 7-8mm to ensure sealing and pressure bearing capacity (such as a pressure test of 30MPa).

2. Manufacturing process

– Surface treatment: Copper pipes are coated with clear varnish or electrophoretic paint, and aluminum fins are anodized to enhance corrosion resistance.

– Internal cleanliness: The high-temperature vacuum drying process ensures that the refrigerant flow path is free of impurities and passes leak detection.

VIDEO INTRODUCTION

VIDEO INTRODUCTION

Send Inquiry

You Might Also Like

-

Precision Copper Tube Fin Evaporators for Food Processing and Cold Storage

-

Enhanced surface aluminum finned evaporator coil

-

High-efficiency and energy-saving copper tube aluminum fin evaporator, core component of commercial display case and beer cabinet refrigeration system.

-

Long-Lasting Finned heat exchangers for Dehumidification and Drying Systems

-

High-Efficiency Copper Tube Aluminum Fin Condensers & Evaporators for HVAC Systems

-

Internally threaded copper tube aluminum foil finned condenser,