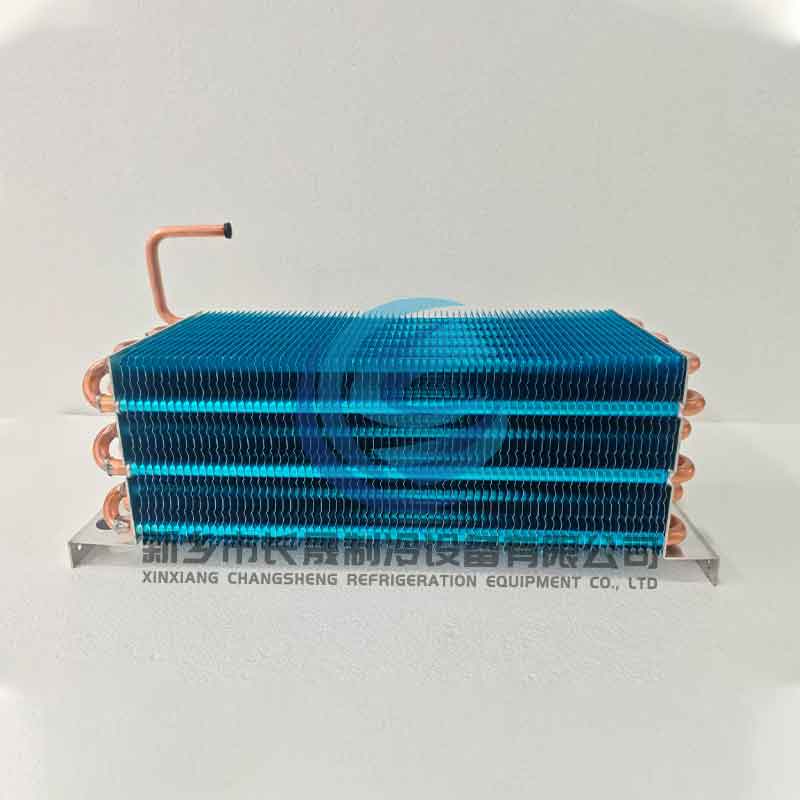

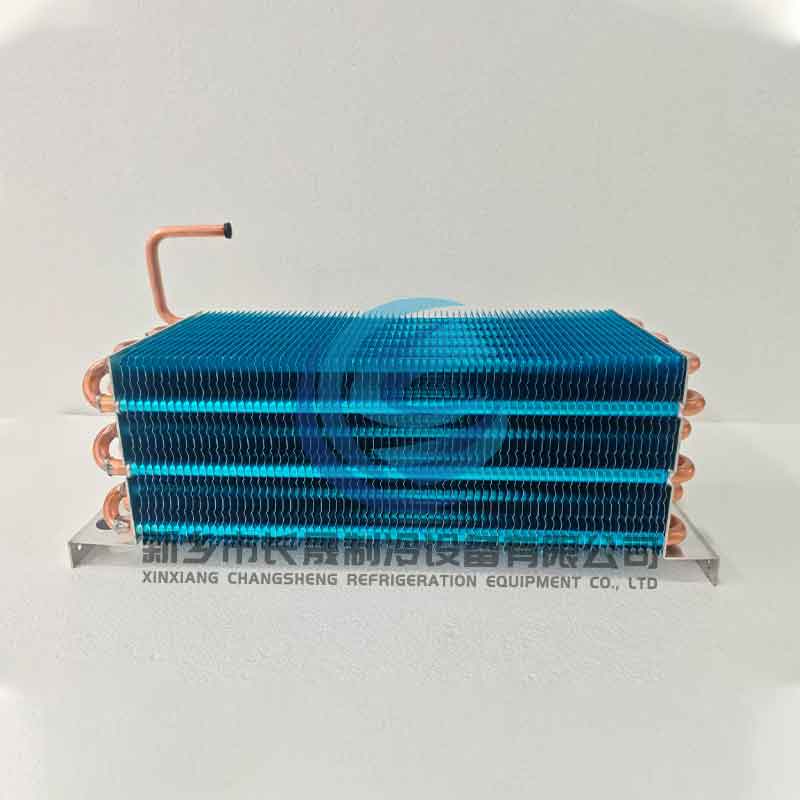

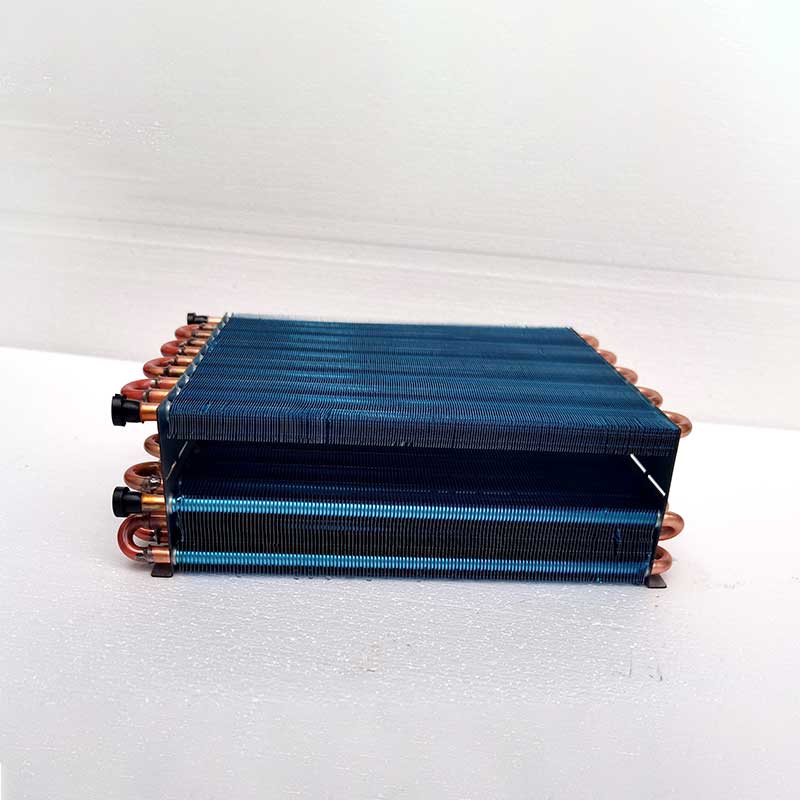

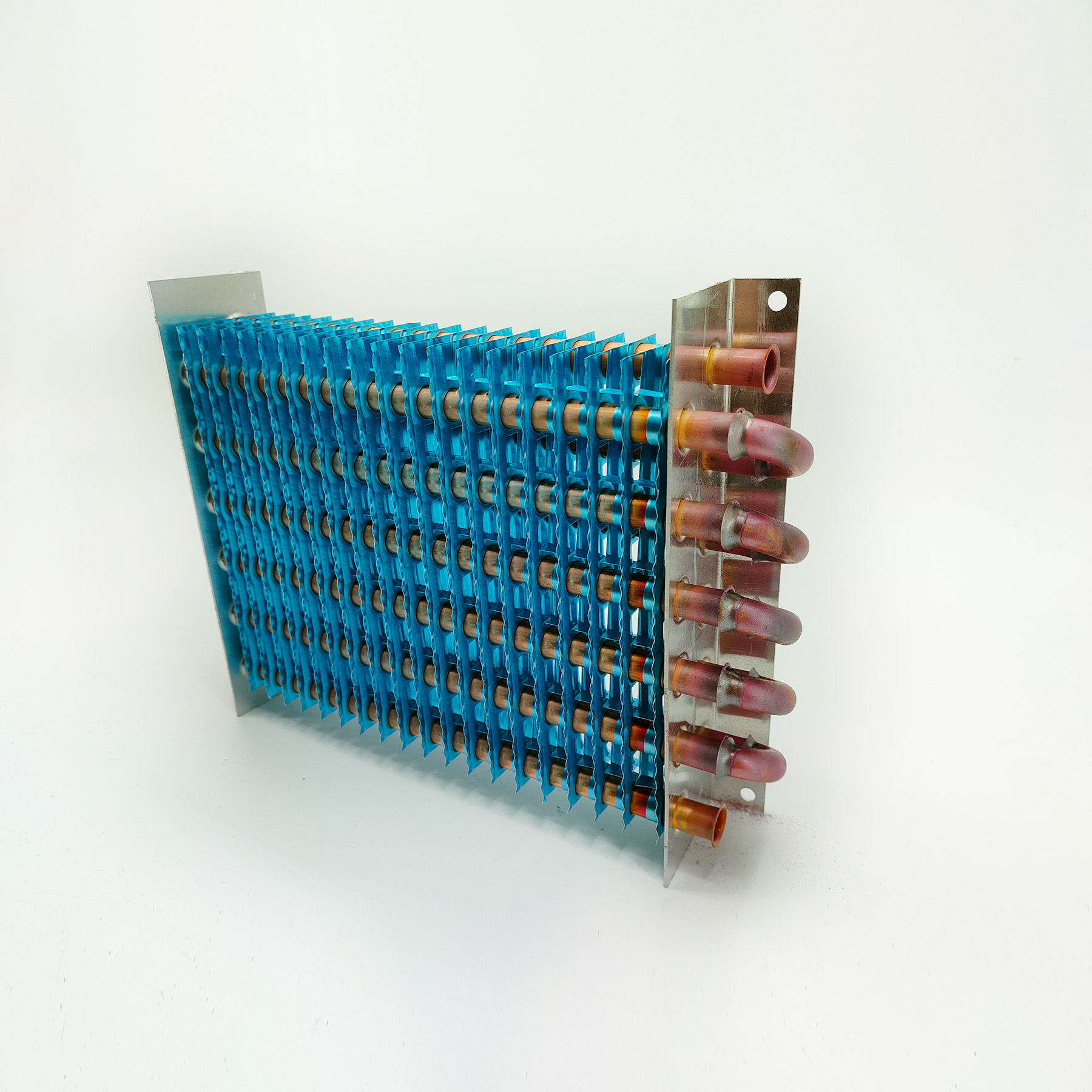

Custom copper tube fin evaporator

The copper tube fin evaporator is a highly efficient heat exchange device. Its core structure is made of copper tube (base tube) and aluminum fin (extended surface) tightly combined through mechanical expansion or hydraulic expansion process. It significantly improves the heat exchange efficiency by increasing the heat transfer area (fin surface area + base tube surface area).

Products Description

Customized copper tube fin evaporator is a non-standard high-efficiency partition wall heat exchange equipment specially designed and manufactured according to the user’s specific needs (such as size, power, working conditions, medium, etc.).

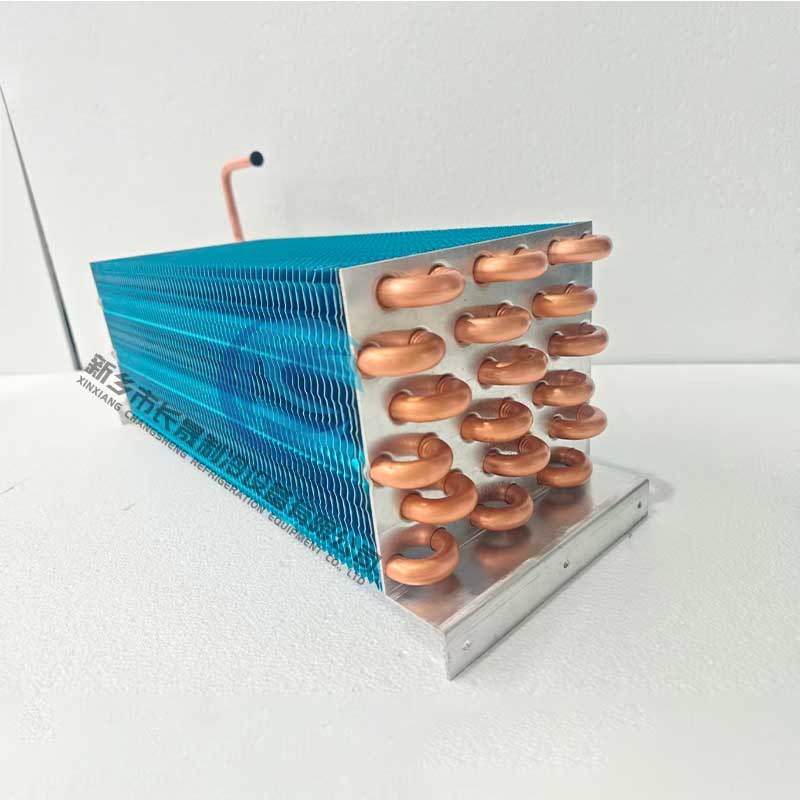

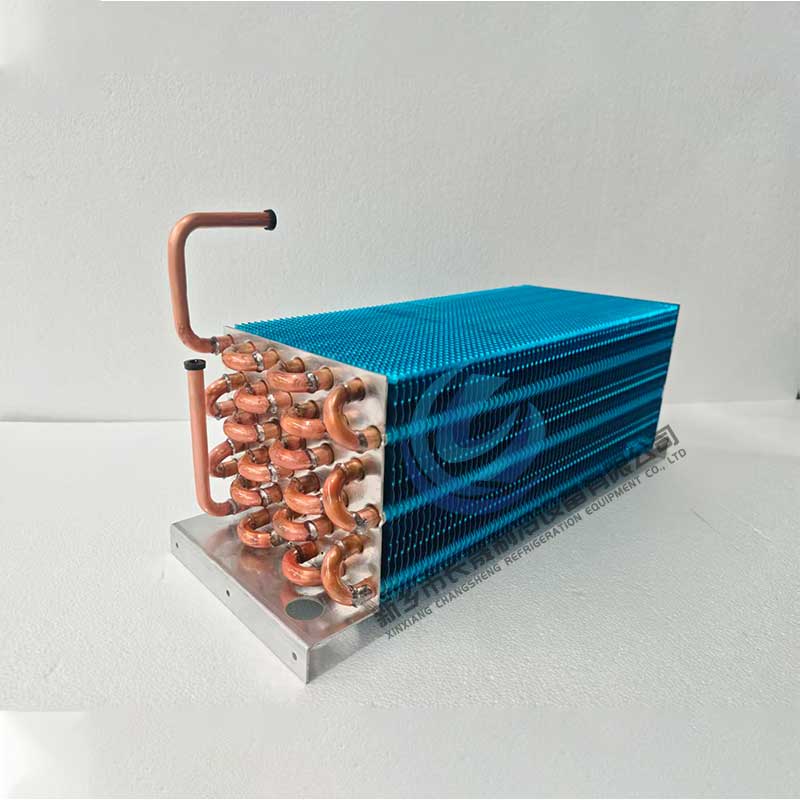

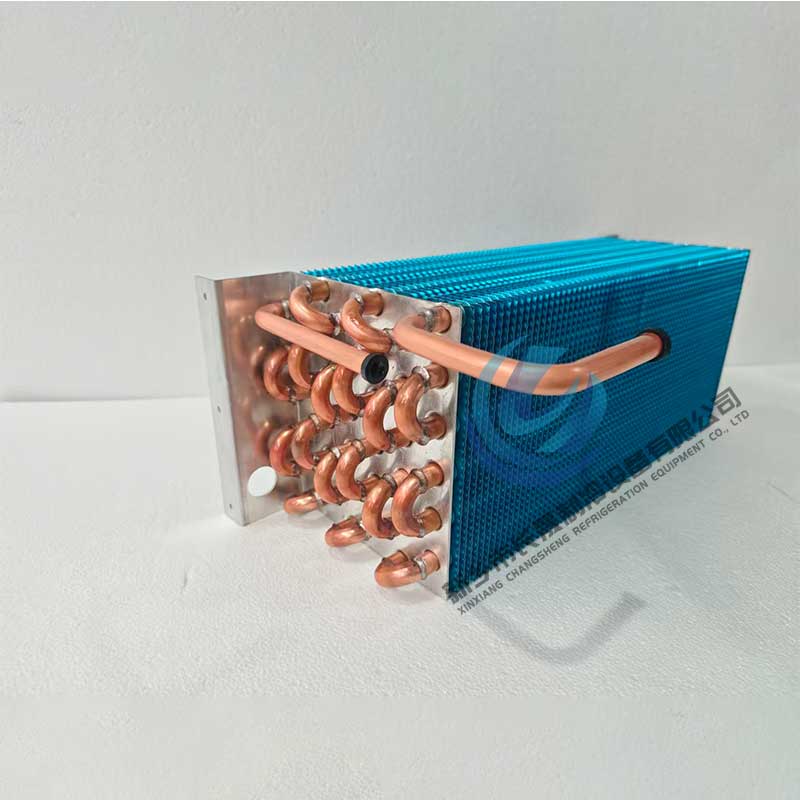

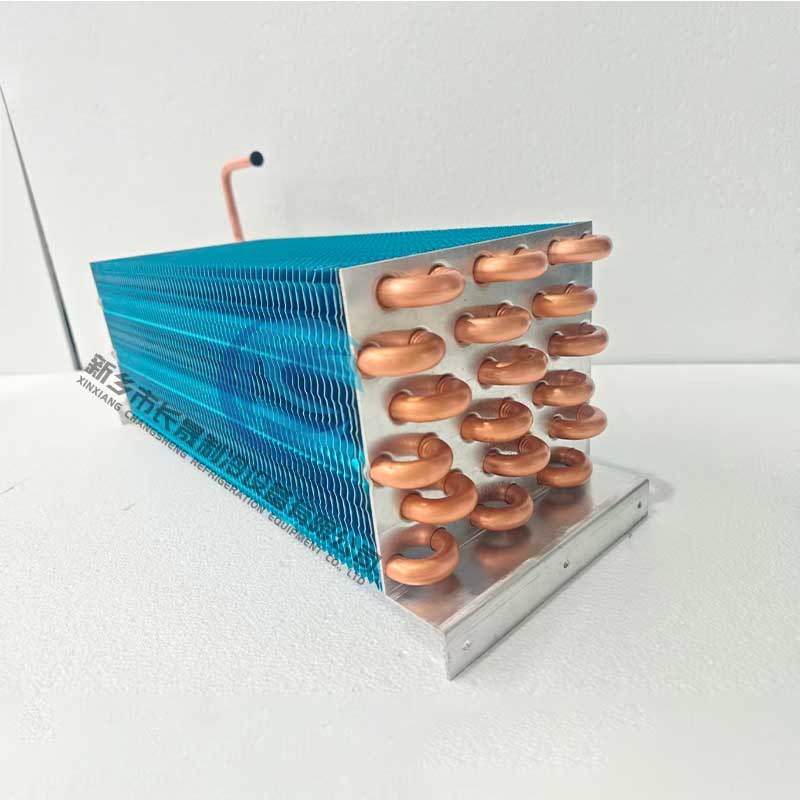

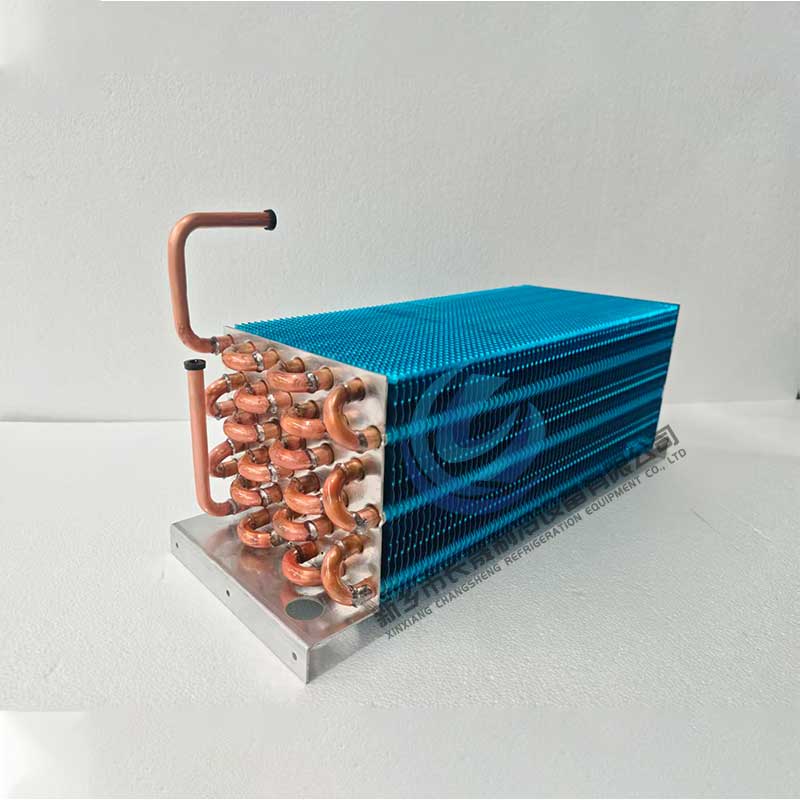

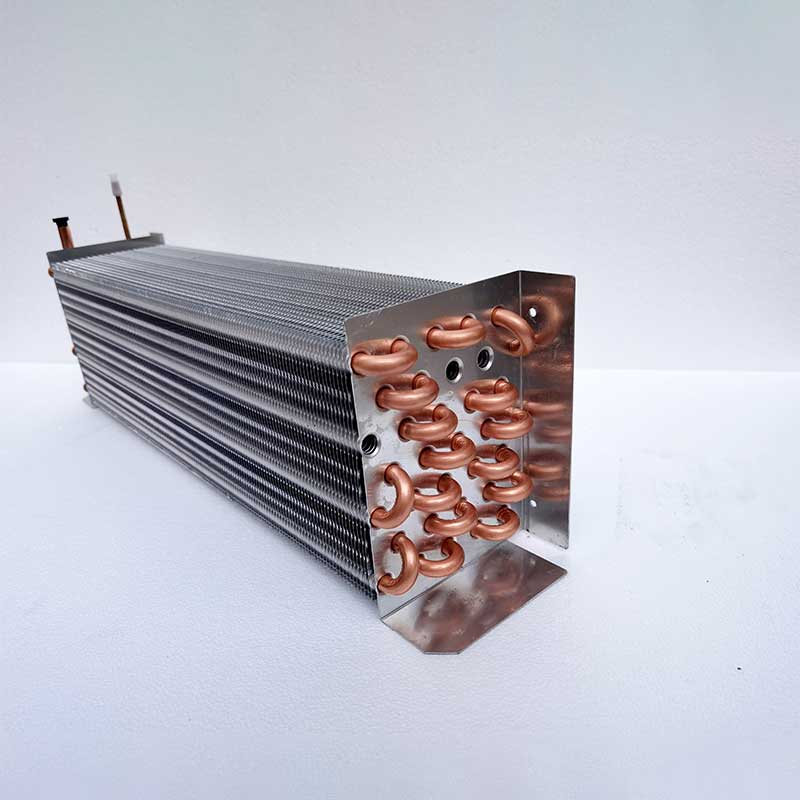

Basic Structure: It is made of copper tubes and aluminum fins tightly bonded together through processes such as mechanical tube expansion.

The copper tubes serve as internal flow channels, carrying the refrigerant (such as R22, R410A, etc.) and evaporating it to absorb heat. Copper tubes offer excellent thermal conductivity, corrosion resistance, and compressive strength.

The aluminum fins fit tightly around the copper tubes, their core function being to significantly increase the contact area with the air, thereby enhancing heat exchange efficiency on the air side while also achieving lightweight design.

Operating Principle: Liquid refrigerant flows within the copper tubes, absorbing heat from the outside air and evaporating into a gaseous state. Simultaneously, a fan forces air through the gaps between the fins, cooling and dehumidifying the air as it loses heat.

The Core Meaning of “Customization”: This is the key differentiator from standard products. Customization is typically reflected in:

Size and Shape: Perfectly adapted to the installation space of the customer’s equipment.

Heat Transfer Capacity: Precisely calculated and designed based on the required cooling capacity and temperature differential.

Fin Spacing and Form: Adjust according to the operating environment (e.g., cleanliness and humidity) to prevent dust accumulation and rapid frost formation.

Port Location and Form: Compatible with existing piping systems.

Working Medium and Pressure: Suitable for different refrigerants or coolants, and meeting corresponding pressure requirements.

FAQ

Q1: How is quality ensured?

A1: we have a one year quality warranty B L issue date. If the product does not work property as described, and the problem is proven to be at our fault, we will provide exchange services for the same specific item.

Q2: Do you provide OEM or ODM service?

A2: Yes. We can produce G-air standard products under customer brand or modify the products to satisfy customers personalized requirements, or work together with customer to design and produce a totally new products.

Q3: How long can I get the feedback after sending the inquiry?

A3:Usually you will get feedback within 30 minutes during the office hours and 12 hours after office hours.

Q4: How long is the production lead time?

A4: Usually the production lead time will be 20 days once order confirmed. Sometimes we have a few.

Q5: How do you make our business long-term and good relationship?

A5: We keep good quality and competitive price to ensure our customers benefit , We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Send Inquiry

You Might Also Like

-

Coca-Cola Beverage Cabinet KSV Series Refrigerator Freezer Evaporator

-

Evaporator Refrigeration plate Freezer refrigerator Freezer Refrigerated display cabinet Freezer Copper tube fin air-cooled condenser

-

Freezer display cabinet vertical cabinet cake cabinet pastry cabinet evaporator condenser pure copper tube

-

Air-cooled evaporator condenser Display cabinet cake cabinet refrigerator freezer refrigerator copper tube aluminum fin evaporator

-

Roll Bond Aluminum Evaporator

-

Coper tube Aluminum Fins Evaporator