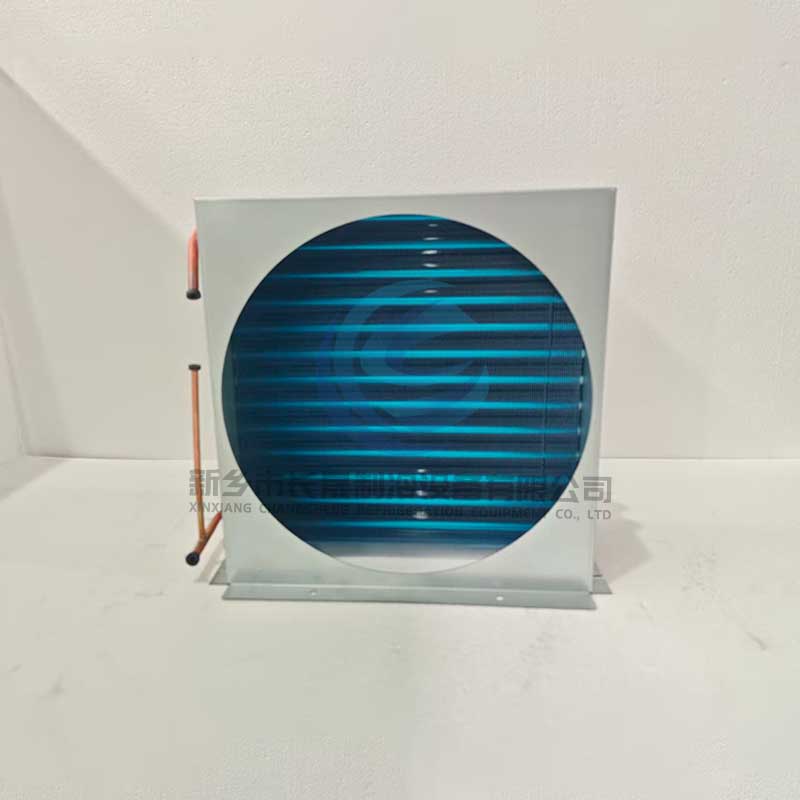

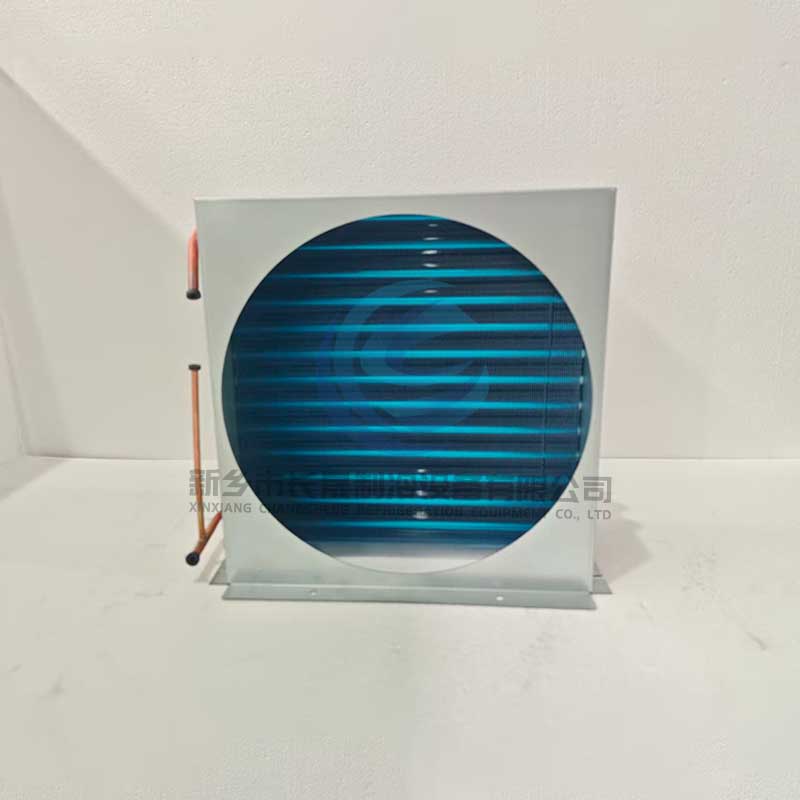

Custom Copper Finned Tube Condensers | Tailored for Your Heat Pump & Chiller Applications

Custom Copper Finned Tube Condensers | Tailored for Your Heat Pump & Chiller Applications

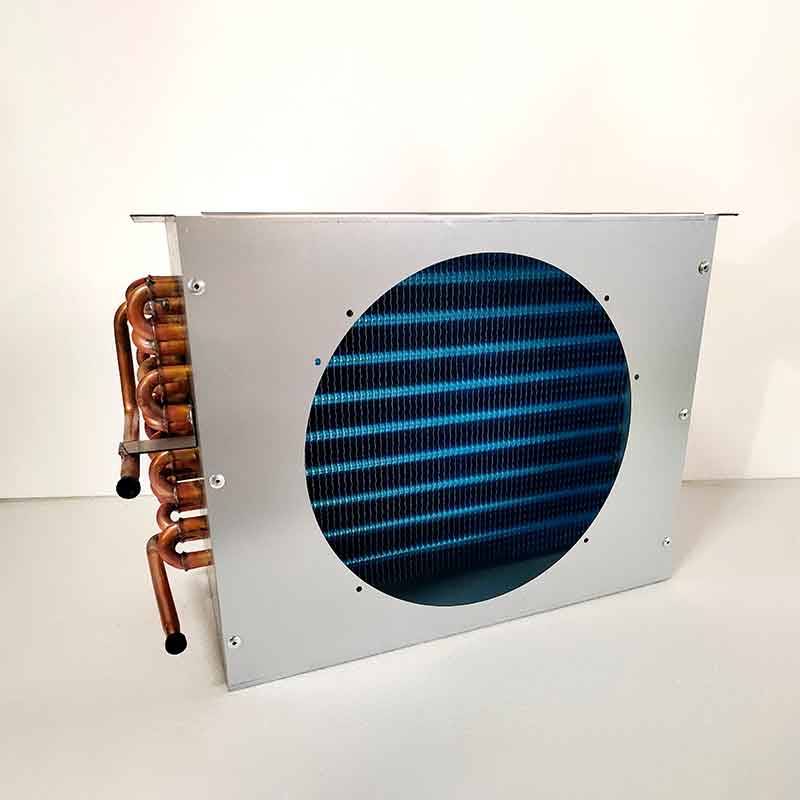

Products Description

Are you looking for a reliable heat exchange solution for heat pumps or chillers with non-standard dimensions or special operating conditions? As a professional copper tube fin condenser manufacturer, we understand that a one-size-fits-all solution doesn’t meet all needs. Our core service is to provide you with a fully customized copper tube fin condenser, ensuring it perfectly matches your equipment and maximizes performance.

一、Our Core Product: What is a Copper Tube Fin Condenser?

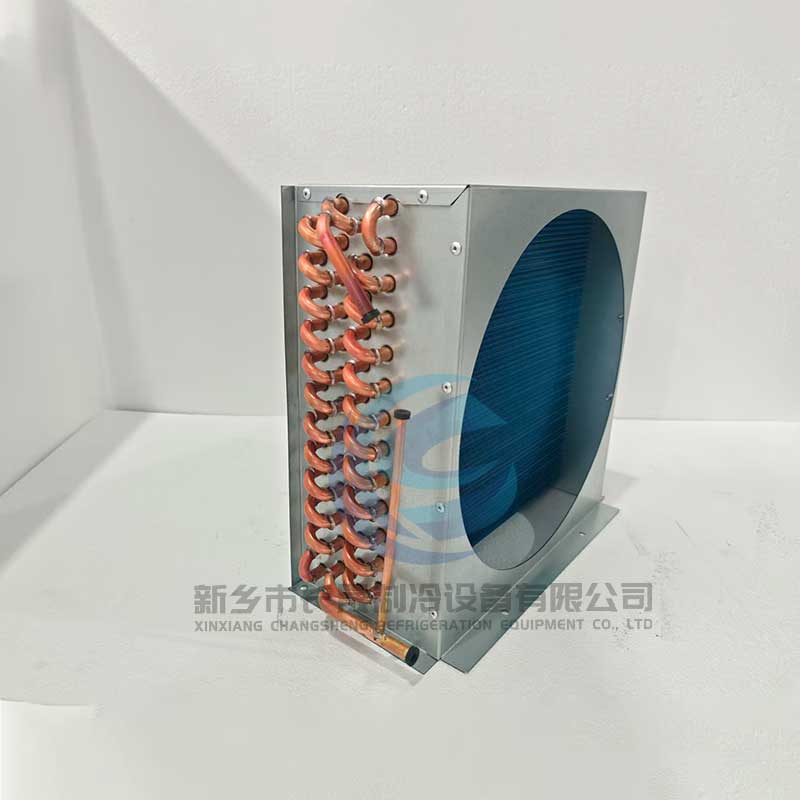

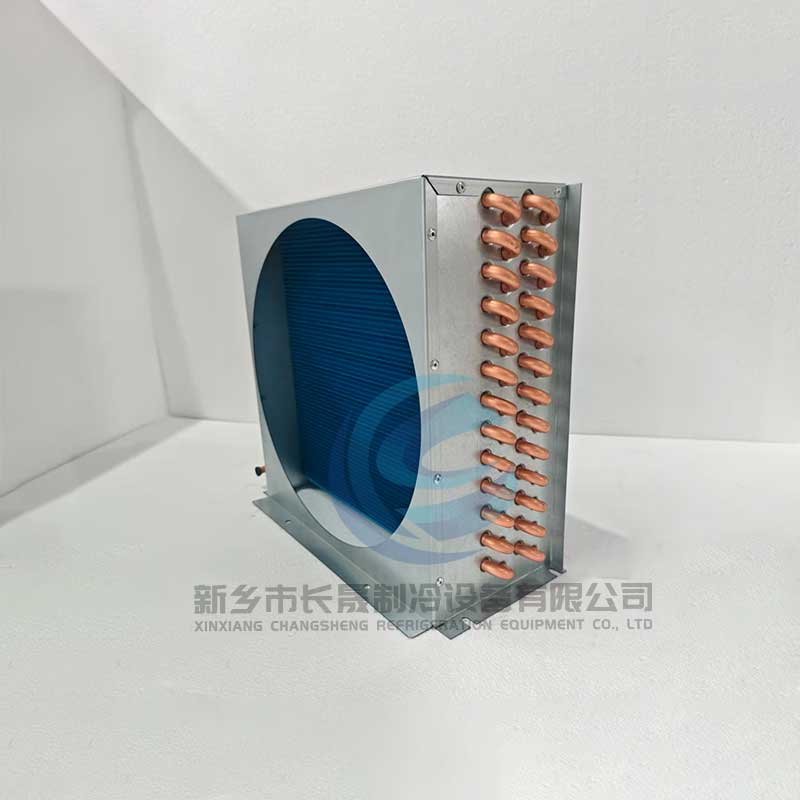

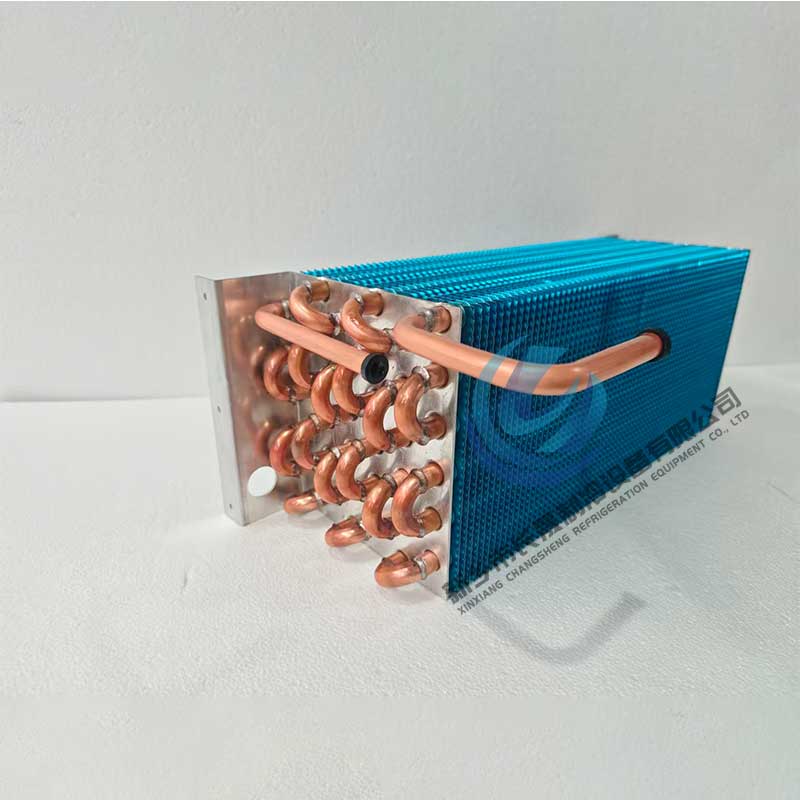

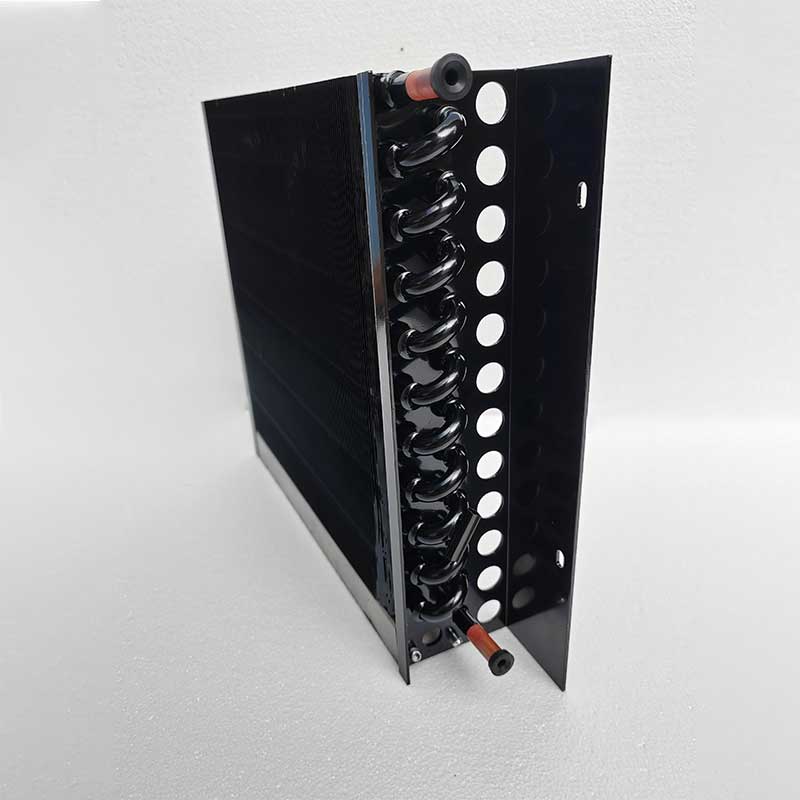

The copper tube fin condenser is a highly efficient heat exchange device with the following core structure:

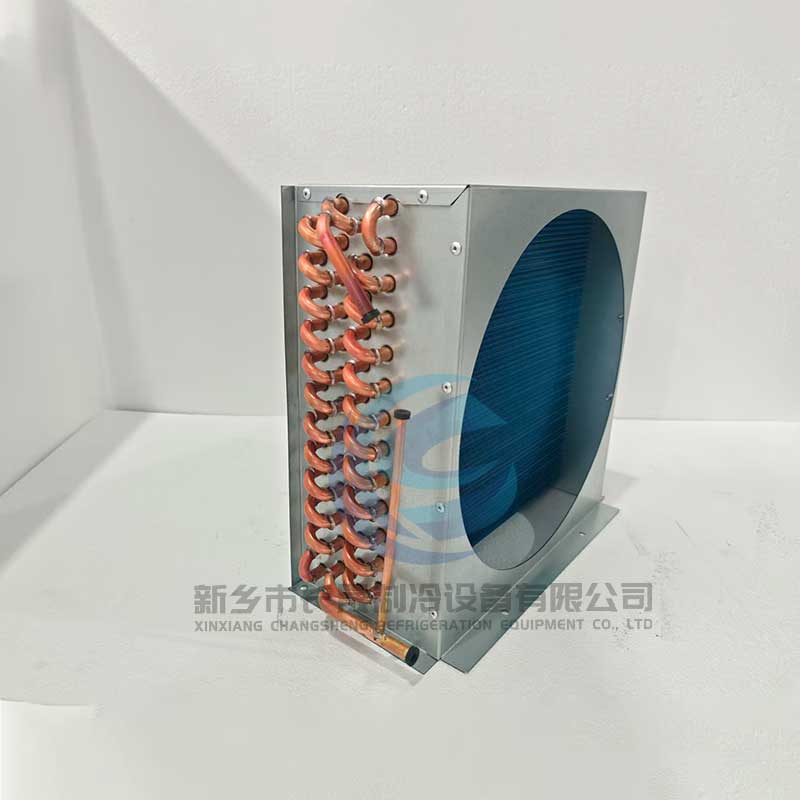

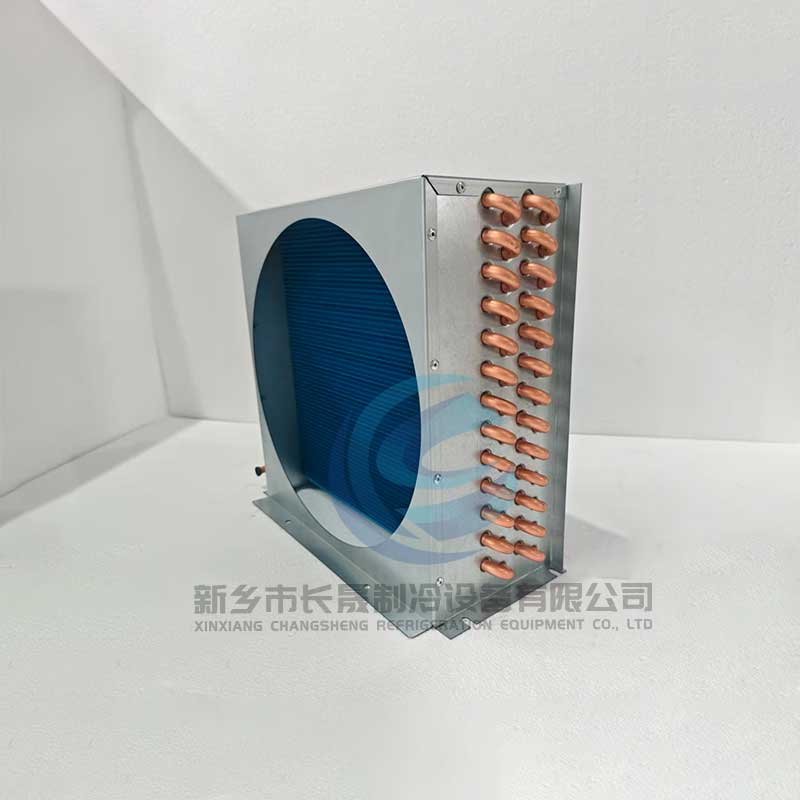

Core Tube: High-quality, highly thermally conductive copper tubes serve as channels for refrigerant circulation and primary heat exchange, offering excellent corrosion resistance and sealing.

Reinforced Fins: Typically hydrophilic aluminum foil fins, tightly bonded to the copper tubes through an advanced mechanical expansion process, significantly increase the secondary heat exchange area.

This “copper tube + aluminum fin” combination ensures optimal thermal conductivity while achieving a perfect balance between lightweight and cost-effectiveness, making it an ideal choice for equipment such as heat pumps and chillers.

Our Core Advantages: Why Choose Our Customization Services?

1. Precision Engineering Matching:

We don’t just manufacture products, we provide solutions. Through customization, we ensure that each condenser:

Fits perfectly within your equipment’s available installation space.

Meets your system’s precise cooling/heating requirements.

Operates stably at specified operating pressures and temperatures.

2. Unparalleled Flexibility and Expertise:

Dimensional Flexibility: Whether you require unconventional lengths, widths, heights, or a unique number of tube rows, we can accommodate.

Technical Adaptability: We can provide customized designs based on different refrigerants (such as R410A, R134a, R32, etc.), environmental conditions, and performance requirements.

Engineering Support: Our team of engineers will work closely with you, providing expert technical support from concept design to production drawings.

3. Superior Quality and Durability:

Material Selection: All copper tubes meet ASTM standards, and aluminum fins feature an anti-corrosion coating.

Exquisite Craftsmanship: A mechanical tube expansion process ensures tight integration of the tube segments, minimizes contact thermal resistance, and maintains efficiency over long-term use.

Strict Testing: Every product undergoes rigorous pressure leak testing (such as helium mass spectrometry) and performance testing to ensure reliability and safety.

4. One-Stop OEM/ODM Services:

We are more than just a supplier; we are your manufacturing partner. We offer a full range of services, from processing based on supplied drawings and samples to custom-designed (ODM) designs. We are happy to sign non-disclosure agreements (NDAs) to protect your intellectual property.

Factory Showcase

Customization Process: How do we work together?

Our customization process is simple, transparent, and efficient:

Consultation and Requirements Analysis: You contact us by email or phone to provide your initial requirements.

Technical Parameter Confirmation: You provide key technical specifications (see the table below) or directly share your design drawings/samples.

Design and Quotation: Our team of engineers will perform design calculations and provide you with a detailed proposal and competitive quotation within 48 hours.

Agreement and Payment: Both parties confirm the technical proposal and commercial terms, sign the contract, and pay the deposit.

Production and Quality Control: We begin production and keep you informed of progress. Quality inspections are performed at key milestones.

Shipping and After-Sales: After final inspection, the product is properly packaged and shipped. We provide comprehensive after-sales support and technical services.

VIDEO INTRODUCTION

Send Inquiry

You Might Also Like

-

Precision Copper Tube Fin Evaporators for Food Processing and Cold Storage

-

Copper tube aluminum fin condenser: a core component of commercial display case refrigeration systems.

-

High-efficiency and energy-saving copper tube aluminum fin evaporator, core component of commercial display case and beer cabinet refrigeration system.

-

Long-Lasting Finned heat exchangers for Dehumidification and Drying Systems

-

OEM/ODM Copper-Aluminum Fin Heat Exchangers for Diverse Industrial Applications

-

Custom Industrial Copper Tube Fin Heat Exchangers for Refrigeration & Cooling Plants