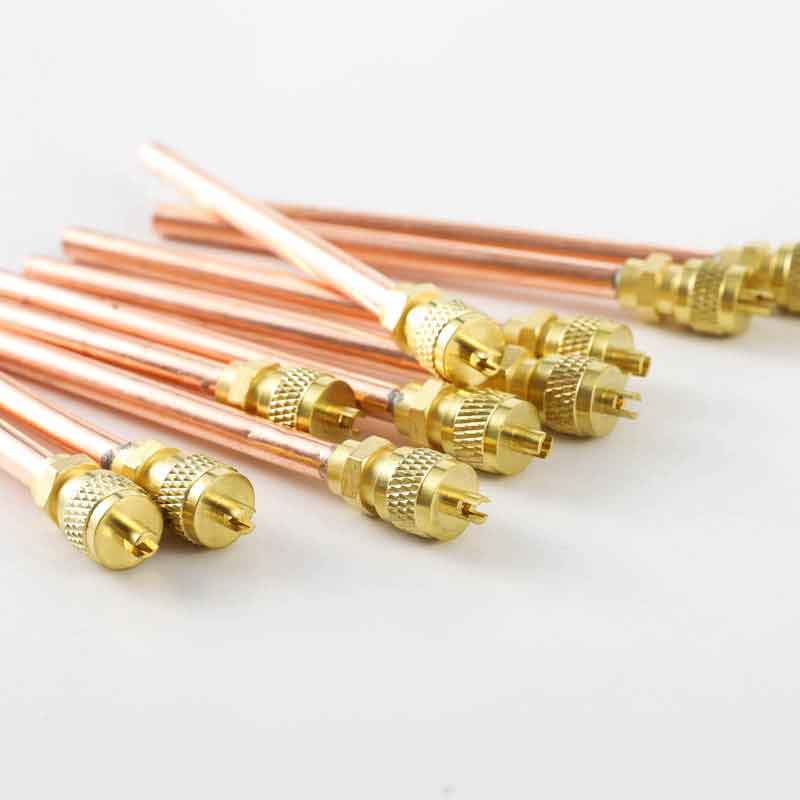

Air conditioning and refrigeration accessories

A refrigeration accessory filter drier is a sealed device filled with a desiccant (moisture-absorbing material) and filter media. Its primary function is to remove moisture and solid impurities from the refrigerant circulation system before the refrigerant enters the throttling device and evaporator. This protects the compressor, prevents system blockage and ice jams, and maintains efficient, reliable, and long-lasting operation of the refrigeration system.

Products Description

1. Location: Install it at a key location in the refrigeration cycle (after the condenser and before the throttling device).

2. Structure: A sealed container containing a desiccant and filter/filter media.

3. Core Function (Dual Function):

Drying (Dehumidification): Utilizes an internal desiccant (such as molecular sieve, silica gel, etc.) to strongly adsorb moisture (H₂O) from the refrigerant. This is key to preventing “ice blockage” (water freezing at the capillary outlet at low temperatures, causing blockage).

Filtration: Utilizes an internal metal filter (typically 100-200 mesh) or porous media such as sintered metal/ceramic to intercept and capture solid particulate impurities in the refrigerant. These impurities may include:

Weld slag, metal debris, and oxides left over from system manufacturing, installation, or maintenance.

Minor metal wear particles generated during compressor operation.

Impurities shed from the inner wall of the pipe.

Potassium powder produced by the desiccant or sealing material (common in inferior products). 4. Core Purpose (Protecting the System):

Protecting the compressor: Preventing impurities from entering the compressor and scratching precision components such as the cylinder wall, piston, and bearings, thereby preventing wear, seizure, or burnout. Preventing moisture from chemically reacting with the refrigerant and refrigeration oil to generate acidic substances that could corrode the motor windings and components

Factory Showcase

FAQ

Q1: How is quality ensured?

A1: we have a one year quality warranty B L issue date. If the product does not work property as described, and the problem is proven to be at our fault, we will provide exchange services for the same specific item.

Q2: Do you provide OEM or ODM service?

A2: Yes. We can produce G-air standard products under customer brand or modify the products to satisfy customers personalized requirements, or work together with customer to design and produce a totally new products.

Q3: How long can I get the feedback after sending the inquiry?

A3:Usually you will get feedback within 30 minutes during the office hours and 12 hours after office hours.

Q4: How long is the production lead time?

A4: Usually the production lead time will be 20 days once order confirmed. Sometimes we have a few.

Q5: How do you make our business long-term and good relationship?

A5: We keep good quality and competitive price to ensure our customers benefit , We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Send Inquiry

You Might Also Like

-

Air conditioning refrigerant fluorine filling tube three color filling tube R22 R134 R410a refrigerant filling tube fluorine filling tube

-

Copper 90 degree equal diameter elbow

-

Copper U-shaped elbow

-

Copper Y-type tee welding

-

Copper reducer pipe joint

-

Condenser liquid gas distribution head distribution head porous brass accessories