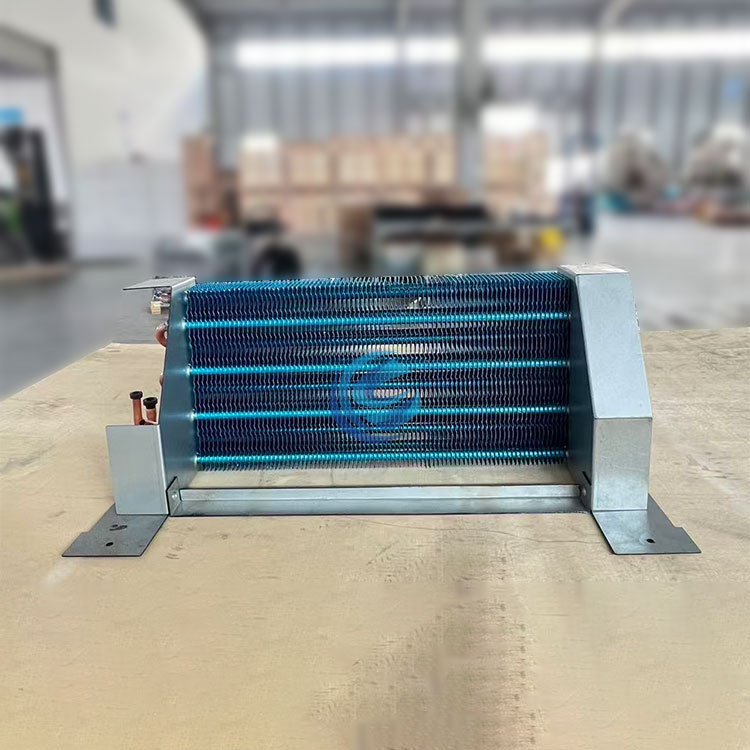

High-Efficiency Copper Tube Aluminum Fin Condensers & Evaporators for HVAC Systems

We offer professional OEM/ODM services. We support production based on drawings, or collaborative design and customized development based on your technical specifications.

Products Description

Copper tube aluminum fin condenser is a high-efficiency heat exchange equipment, belonging to the gas-liquid or gas-gas condenser type. Its core structure consists of the following two parts:

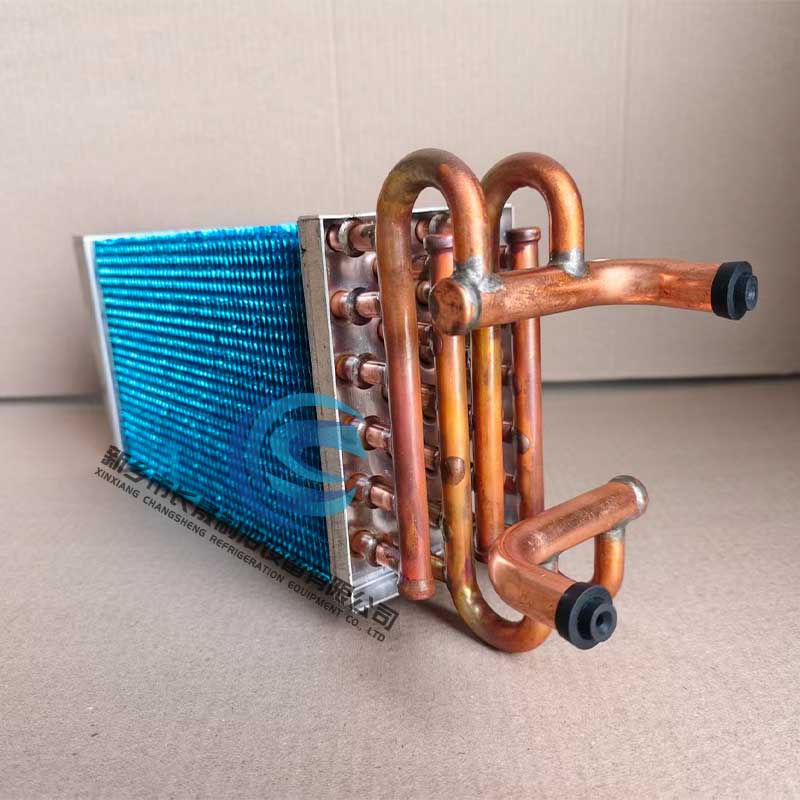

1. Copper tube: As a circulation pipe for heat transfer media (such as refrigerants), copper becomes the core heat transfer material due to its high thermal conductivity (thermal conductivity coefficient is about 400 W/m·K) and corrosion resistance.

2. Aluminum fins: Tightly wrapped around the outer wall of the copper tube through mechanical expansion or welding process to form a dense fin array. Aluminum significantly increases the heat dissipation surface area and improves the overall heat exchange efficiency due to its light weight (density is only 30% of copper) and low cost.

Function: In the refrigeration/heat pump system, the high-temperature and high-pressure gaseous refrigerant is condensed into liquid through heat exchange with the ambient air, releasing latent heat (such as the condensation latent heat of R410A refrigerant is about 200-250 kJ/kg), completing the key link of the refrigeration cycle

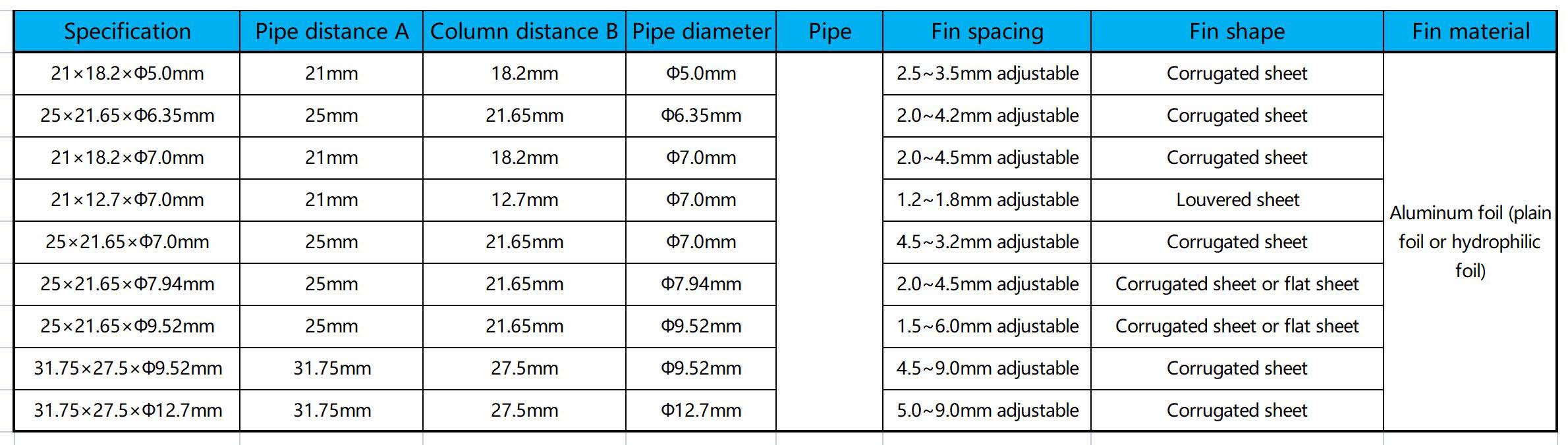

3. Structure and materials – Base tube: Usually a copper tube with a diameter of Φ5~15.88mm and a wall thickness of 0.28~0.6mm. Some of them adopt an internal fin design to enhance the heat transfer in the tube. – Fin: The thickness of the aluminum foil is 0.12mm, and a corrugated or serrated surface is formed by stamping to optimize the airflow disturbance. – Connection process: The copper elbow and the piping adopt a Φ7~8mm specification to ensure the sealing and pressure bearing capacity (such as the pressure test up to 30MPa).

4. Manufacturing process – Surface treatment: The copper tube is dipped in varnish or electrophoretic paint, and the aluminum fin is anodized to improve corrosion resistance. – Internal cleanliness: High temperature vacuum drying process ensures that the refrigerant flow path is free of impurities and passes leak detection.

We are not just a manufacturer, but also your reliable engineering solutions partner. With deep expertise and advanced manufacturing capabilities, we can accurately interpret your design drawings, or collaborate on design and engineering development from scratch based on specific application requirements, performance parameters, and space constraints, ultimately delivering customized heat exchange products that perfectly meet your project requirements.

We are committed to being an extension of your R&D team. From concept sketches to finished product delivery, we provide full engineering support. Whether optimizing existing drawings or creating entirely new designs based on your performance goals (such as heat exchange, energy efficiency, and corrosion resistance), our engineering team will work closely with you to ensure that every product is a solution tailored to your unique application.

Factory Showcase

VIDEO INTRODUCTION

FAQ

Q1: How is quality ensured?

A1: we have a one year quality warranty B L issue date. If the product does not work property as described, and the problem is proven to be at our fault, we will provide exchange services for the same specific item.

Q2: Do you provide OEM or ODM service?

A2: Yes. We can produce G-air standard products under customer brand or modify the products to satisfy customers personalized requirements, or work together with customer to design and produce a totally new products.

Q3: How long can I get the feedback after sending the inquiry?

A3:Usually you will get feedback within 30 minutes during the office hours and 12 hours after office hours.

Q4: How long is the production lead time?

A4: Usually the production lead time will be 20 days once order confirmed. Sometimes we have a few.

Q5: How do you make our business long-term and good relationship?

A5: We keep good quality and competitive price to ensure our customers benefit , We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Send Inquiry

You Might Also Like

-

Precision Copper Tube Fin Evaporators for Food Processing and Cold Storage

-

Copper tube aluminum fin condenser: a core component of commercial display case refrigeration systems.

-

High-efficiency and energy-saving copper tube aluminum fin evaporator, core component of commercial display case and beer cabinet refrigeration system.

-

Long-Lasting Finned heat exchangers for Dehumidification and Drying Systems

-

OEM/ODM Copper-Aluminum Fin Heat Exchangers for Diverse Industrial Applications

-

Custom Industrial Copper Tube Fin Heat Exchangers for Refrigeration & Cooling Plants