finned condenser

The finned condenser is a common heat exchange equipment, mainly used to cool high-temperature and high-pressure gas or steam into liquid. It is designed with many thin fins (fins) inside, which can significantly increase the heat exchange surface area, thereby improving the heat exchange efficiency.

Products Description

The finned condenser is a highly efficient heat exchange device designed to enhance the condensation process in various industrial and commercial applications. It features a unique design that incorporates fins onto the condenser tubes, significantly increasing the surface area for heat transfer. This design allows for more effective cooling, making it ideal for use in refrigeration systems, air conditioning units, and other cooling applications.

Key Features

Enhanced Heat Transfer: The fins on the condenser tubes provide a larger surface area for heat exchange, resulting in more efficient cooling and condensation.

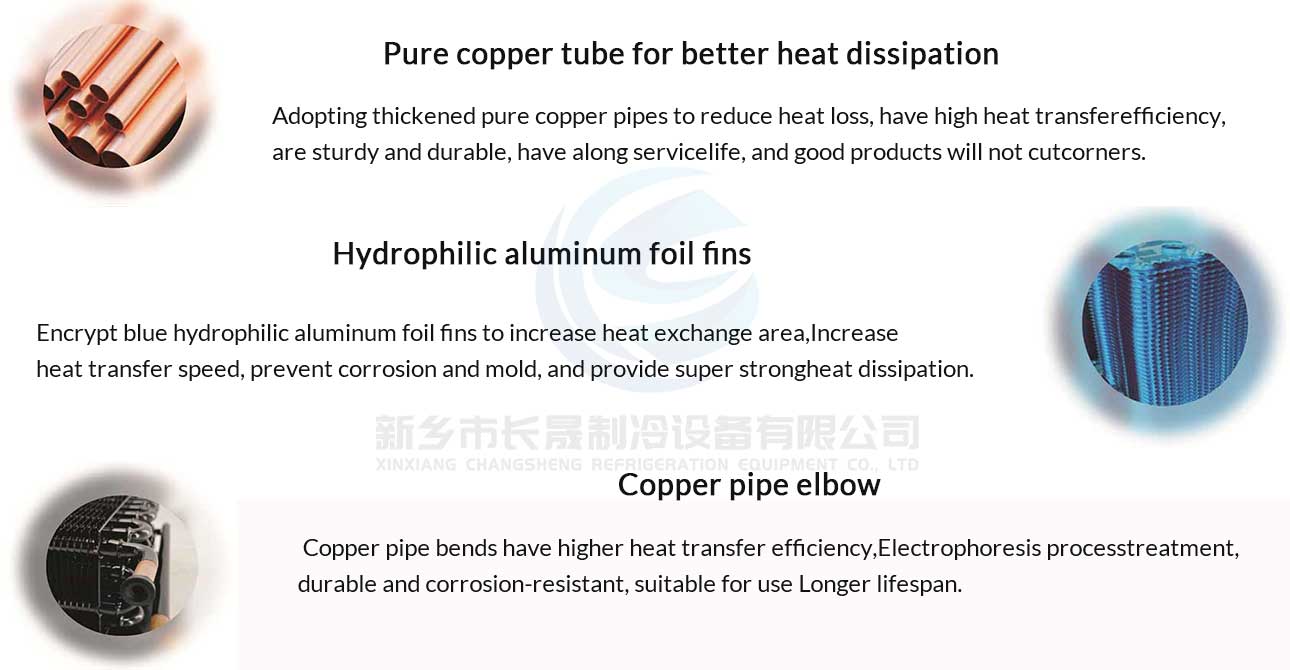

Durable Construction: The finned condenser is built to withstand the rigors of industrial use. The tubes and fins are typically made from high-quality materials such as copper and aluminum, ensuring long-term reliability and performance.

Compact Design: Despite its enhanced heat transfer capabilities, the finned condenser maintains a compact design, making it easy to install and integrate into existing systems.

Versatile Applications: The finned condenser is suitable for a wide range of applications, including refrigeration, air conditioning, and industrial cooling.

Technical Specifications

Material: Copper tubes with aluminum fins

Tube Diameter: Available in various standard sizes to meet specific application requirements

Fin Type: Options include louvered, corrugated, and sine wave fins to optimize heat transfer

Heat Transfer Mode: Regenerative, ensuring efficient and effective cooling

Certifications: RoHS, ISO, CE, CCC, ensuring compliance with international quality and safety standards

Materials

Application Scenarios

Workshop

VIDEO INTRODUCTION

FAQ

Q1: How can I make an order?

A1: Inquiry → Quotation → Order → Payment → Delivery → Deal → Feedback

Q2: What is your terms of payment?

A2: T/T 30% as deposit, and 70% before delivery. We ll show you the photos of the products and packages before you pay the balance.

Q3: What is your terms of delivery?

A3:Convenience by Western Union/Money Gram/Trade Assurance/Paypal/T/T etc.

Q4: How about your delivery time?

A4: Generally, it will take 15 to 40 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5: Can you produce according to the samples?

A5: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6: What is your sample policy?

A6: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7: Do you test all your goods before delivery?

A7: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A8: 1. We keep good quality and competitive price to ensure our customers benefit ; 2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Q9: What is your Minimum Order Quality?

A9: Different products have different MOQ,but we can sell you even one piece if we have stock the model of you need.

Send Inquiry

You Might Also Like

-

Precision Copper Tube Fin Evaporators for Food Processing and Cold Storage

-

Copper tube aluminum fin condenser: a core component of commercial display case refrigeration systems.

-

High-efficiency and energy-saving copper tube aluminum fin evaporator, core component of commercial display case and beer cabinet refrigeration system.

-

Long-Lasting Finned heat exchangers for Dehumidification and Drying Systems

-

OEM/ODM Copper-Aluminum Fin Heat Exchangers for Diverse Industrial Applications

-

Custom Industrial Copper Tube Fin Heat Exchangers for Refrigeration & Cooling Plants