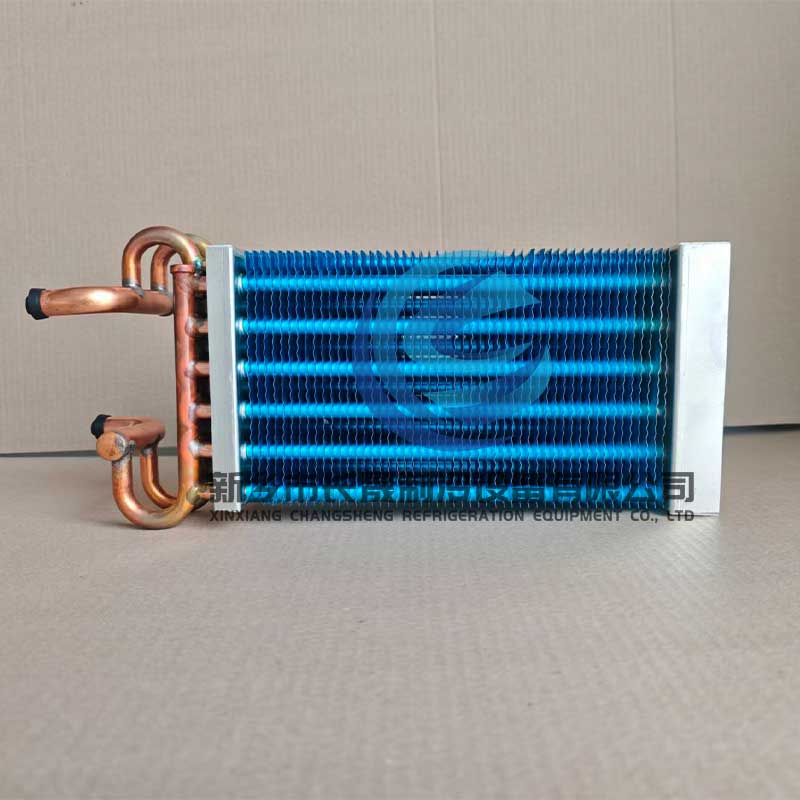

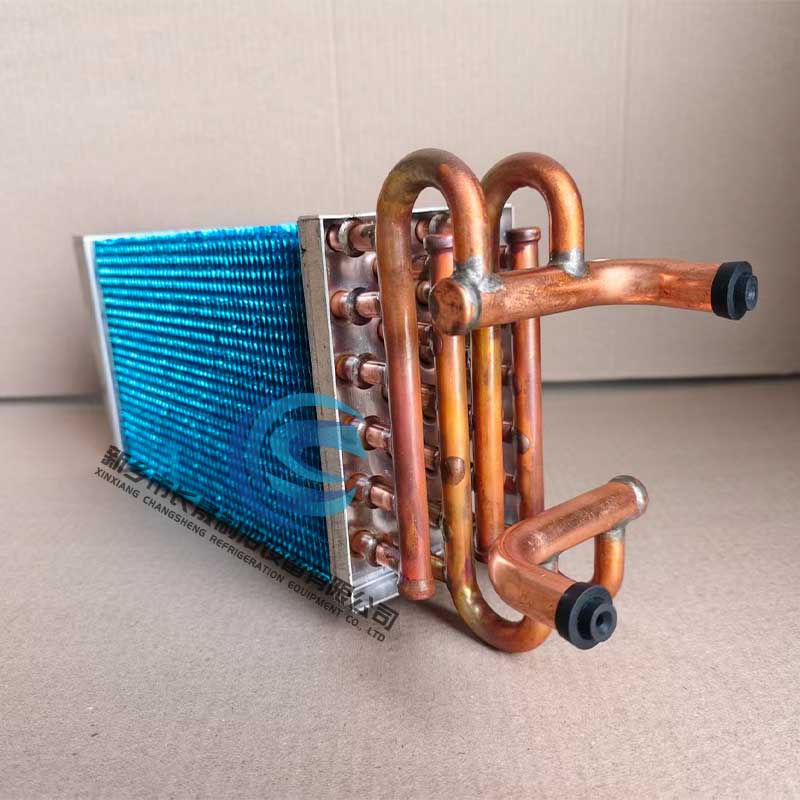

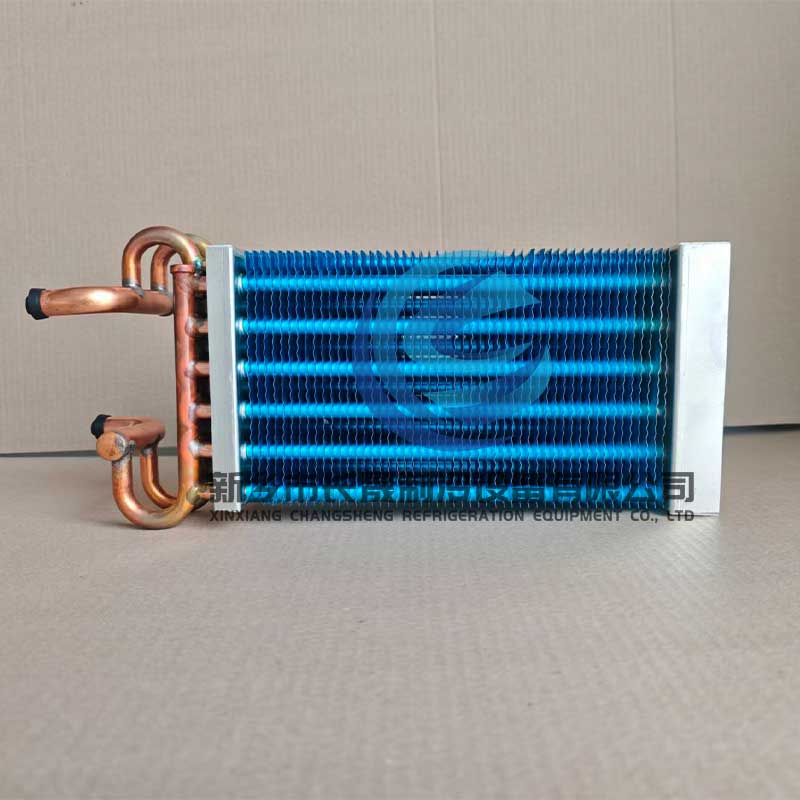

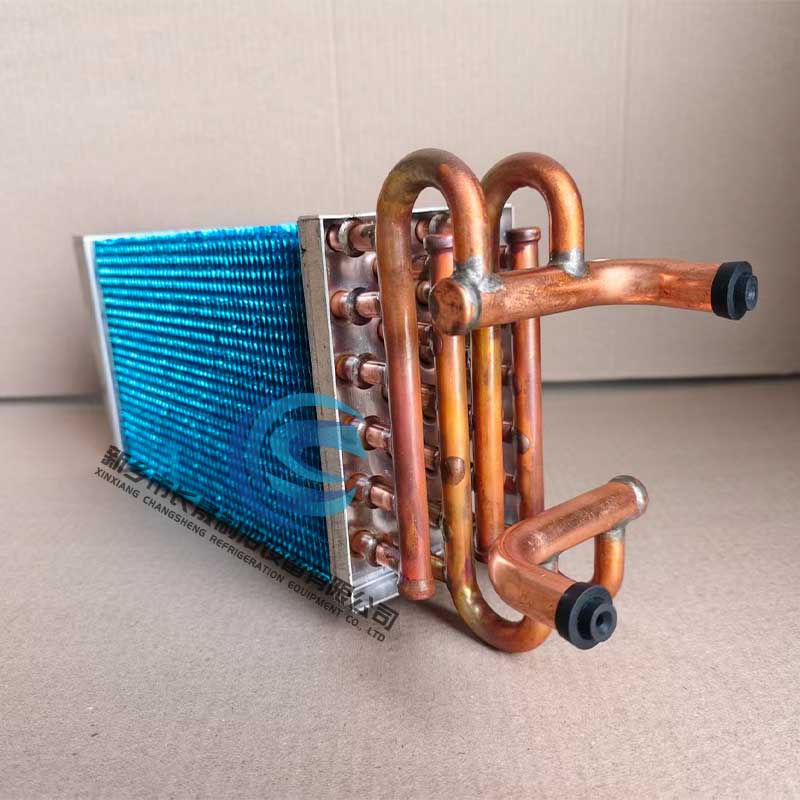

Customized evaporator, condenser, and coil; high-efficiency refrigeration; copper tube and aluminum fin heat exchanger.

Contact our expert team now for a free customized solution consultation and quote!Send us your technical requirements and let us become your most trusted partner for heat exchange solutions.

Products Description

Copper tube finned condensers are highly efficient heat exchange devices. Their core structure consists of:

Core Tubing: High-quality, high-thermal-conductivity copper tubes, serving as the channel for refrigerant flow and primary heat exchange, possessing excellent corrosion resistance and sealing properties.

Reinforced Fins: Typically hydrophilic aluminum foil fins, tightly bonded to the copper tubes using advanced mechanical expansion technology, significantly increasing the secondary heat exchange area.

This “copper tube + aluminum fin” combination achieves a perfect balance between lightweight design and cost-effectiveness while ensuring optimal thermal conductivity, making it an ideal choice for heat pumps, chillers, and other similar equipment.

Our Core Advantages: Why Choose Our Customized Services?

1. Precise Engineering Match:

We don’t just manufacture products; we provide solutions. Through customization, we ensure that every condenser:

fits perfectly with the available installation space in your equipment.

Meets the precise cooling/heating requirements of your system.

Operates stably at specified operating pressures and temperatures.

2. Unparalleled Flexibility and Expertise:

Flexible Sizes: Whether you need unconventional lengths, widths, heights, or special pipe bank designs, we can achieve it.

Technical Adaptability: We can design specifically for different refrigerants (such as R410A, R134a, R32, etc.), environmental conditions, and performance requirements.

Engineering Support: Our team of engineers will work closely with you, providing professional technical support from conceptual design to production drawings.

3. Superior Quality and Durability:

Selected Materials: All copper tubing conforms to ASTM standards, and aluminum fins have an anti-corrosion coating.

Superior Craftsmanship: Utilizing mechanical tube expansion technology, we ensure a tight bond between the tube segments, low contact thermal resistance, and no efficiency degradation over long-term use.

Rigorous Testing: Every product undergoes rigorous pressure leak testing (such as helium mass spectrometry leak testing) and performance testing before leaving the factory, guaranteeing reliability and safety.

4. One-Stop OEM/ODM Service: We are not just a supplier, but your production partner. We offer a full range of services from processing based on provided drawings and samples to complete ODM design according to your requirements, and we are happy to sign confidentiality agreements (NDAs) to protect your intellectual property.

Customization Process: How Do We Collaborate?

Our customization process is simple, transparent, and efficient:

1.Consultation and Needs Analysis: You contact us via email or phone to provide your initial requirements.

2.Technical Parameter Confirmation: You provide key technical parameters (see table below) or directly share your design drawings/samples.

3.Design and Quotation: Our engineering team performs design calculations and provides you with a detailed solution and competitive quotation within 48 hours.

4.Agreement and Payment: Both parties confirm the technical solution and commercial terms, sign a contract, and pay a deposit.

5.Production and Quality Control: We begin production and keep you updated on the progress. Quality checks are conducted at key stages.

6.Shipping and After-Sales Service: After final inspection, the products are properly packaged and shipped. We provide comprehensive after-sales support and technical services.

FAQ

Q1: How is quality ensured?

A1: we have a one year quality warranty B L issue date. If the product does not work property as described, and the problem is proven to be at our fault, we will provide exchange services for the same specific item.

Q2: Do you provide OEM or ODM service?

A2: Yes. We can produce G-air standard products under customer brand or modify the products to satisfy customers personalized requirements, or work together with customer to design and produce a totally new products.

Q3: How long can I get the feedback after sending the inquiry?

A3:Usually you will get feedback within 30 minutes during the office hours and 12 hours after office hours.

Q4: How long is the production lead time?

A4: Usually the production lead time will be 20 days once order confirmed. Sometimes we have a few.

Q5: How do you make our business long-term and good relationship?

A5: We keep good quality and competitive price to ensure our customers benefit , We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Send Inquiry

You Might Also Like

-

Precision Copper Tube Fin Evaporators for Food Processing and Cold Storage

-

Copper tube aluminum fin condenser: a core component of commercial display case refrigeration systems.

-

High-efficiency and energy-saving copper tube aluminum fin evaporator, core component of commercial display case and beer cabinet refrigeration system.

-

Long-Lasting Finned heat exchangers for Dehumidification and Drying Systems

-

OEM/ODM Copper-Aluminum Fin Heat Exchangers for Diverse Industrial Applications

-

Custom Industrial Copper Tube Fin Heat Exchangers for Refrigeration & Cooling Plants