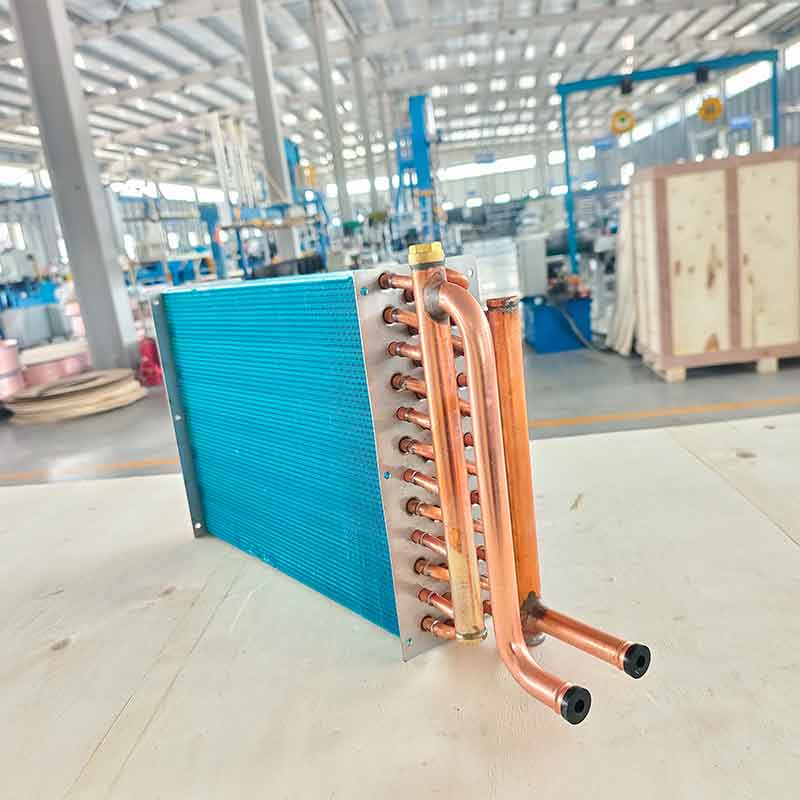

Copper tube aluminum fin heat exchanger for marine cruise ship heating equipment

This product is an air heating terminal specifically designed for central heating systems on ships, particularly cruise ships. It utilizes a high-temperature heat source (such as hot water, steam, or hot oil) to release heat within copper tubes. A fan forces air through the aluminum fins, heating the cooled air. This provides comfortable, efficient, and reliable heating to various cabins on the ship, such as cabins, dining rooms, and corridors.Simply put, it's the core heat-generating component of a cruise ship's "radiator" or "fan heater."

Products Description

Copper Tubes

Purpose: Serves as an internal flow channel, carrying high-temperature heat transfer media (hot water/steam/hot oil).

1. Why Copper Tubes?

Excellent Corrosion Resistance: The marine environment is characterized by high salt content and humidity, making it extremely corrosive. Compared to ordinary steel, copper tubes offer superior resistance to seawater and salt spray corrosion, making them the preferred material for marine equipment.

High Thermal Conductivity: Efficiently transfers heat from the heat transfer media to the aluminum fins and air.

High Strength and Pressure Resistance: Able to withstand the pressures of heating systems, especially when using steam as the heat transfer media.

Good Ductility: Easily processed into the desired coil shape and offering excellent vibration resistance, making them suitable for use on ships at sea.

2. Aluminum Fins

Purpose: Tightly fitted around the outside of the copper tube, their core function is to significantly increase the heat transfer area and enhance heat transfer efficiency on the air side.

Why Aluminum Fins?

Lightweight: Aluminum’s low density significantly reduces equipment weight, which is crucial for a ship’s load and balance.

Excellent thermal conductivity: Second only to copper, it is a highly cost-effective fin material.

Cost-effectiveness: While maintaining performance, the “copper tube + aluminum fin” combination (rather than all copper) effectively controls costs.

Surface treatment: Aluminum fins are typically treated with a hydrophilic coating or anti-corrosion coating to further enhance their corrosion resistance and prevent condensation and dripping.

3. Heat Exchanger

Functional Positioning: Its role is clearly defined as a wall-type heat exchanger. Two media (heat medium and air) are separated by a metal wall and heat is exchanged through the solid wall without contact.

Operating Mode: It functions as a heater. In contrast to the previously discussed evaporator (which absorbs heat), it is a heat-dissipating element.

4. Dedicated for Marine/Cruise Ship Heating Equipment

Application Scenario: This heat exchanger is not intended for ordinary civilian or industrial use and must be designed and manufactured to meet marine standards.

Core Requirements:

Salt Spray Corrosion Resistance: All materials and surface treatments must be resistant to corrosion from the marine atmosphere.

Vibration and Shock Resistance: The structural design must be robust, capable of withstanding the long-term vibration and occasional shock caused by the ship’s engines and waves.

High Reliability and Safety: Onboard ships, maintenance is extremely difficult, so the equipment must be highly reliable. Furthermore, it must be leak-proof and have a high safety level.

Compact Design: Space is at a premium onboard ships, so the equipment must provide maximum heat transfer per unit volume, requiring a compact design.

Adaptability to Multiple Heat Sources: The equipment must be compatible with the various heat sources used on cruise ships, such as hot water heated by engine waste heat, steam generated by boilers, or high-temperature hot oil.

This high-reliability heating system is specially designed for the harsh marine environment. It features a compact structure featuring corrosion-resistant, pressure-bearing copper tubes and efficient heat conduction aluminum fins. It uses hot water or steam flowing through the copper tubes as a heat source, and a fan drives air across the fins to generate warm air. It is designed to provide stable and comfortable central heating for living spaces on cruise ships. All design and material selection prioritize marine standards, particularly corrosion resistance and vibration resistance.

FAQ

Q1: How is quality ensured?

A1: we have a one year quality warranty B L issue date. If the product does not work property as described, and the problem is proven to be at our fault, we will provide exchange services for the same specific item.

Q2: Do you provide OEM or ODM service?

A2: Yes. We can produce G-air standard products under customer brand or modify the products to satisfy customers personalized requirements, or work together with customer to design and produce a totally new products.

Q3: How long can I get the feedback after sending the inquiry?

A3:Usually you will get feedback within 30 minutes during the office hours and 12 hours after office hours.

Q4: How long is the production lead time?

A4: Usually the production lead time will be 20 days once order confirmed. Sometimes we have a few.

Q5: How do you make our business long-term and good relationship?

A5: We keep good quality and competitive price to ensure our customers benefit , We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Send Inquiry

You Might Also Like

-

Precision Copper Tube Fin Evaporators for Food Processing and Cold Storage

-

Copper tube aluminum fin condenser: a core component of commercial display case refrigeration systems.

-

High-efficiency and energy-saving copper tube aluminum fin evaporator, core component of commercial display case and beer cabinet refrigeration system.

-

Long-Lasting Finned heat exchangers for Dehumidification and Drying Systems

-

OEM/ODM Copper-Aluminum Fin Heat Exchangers for Diverse Industrial Applications

-

Custom Industrial Copper Tube Fin Heat Exchangers for Refrigeration & Cooling Plants