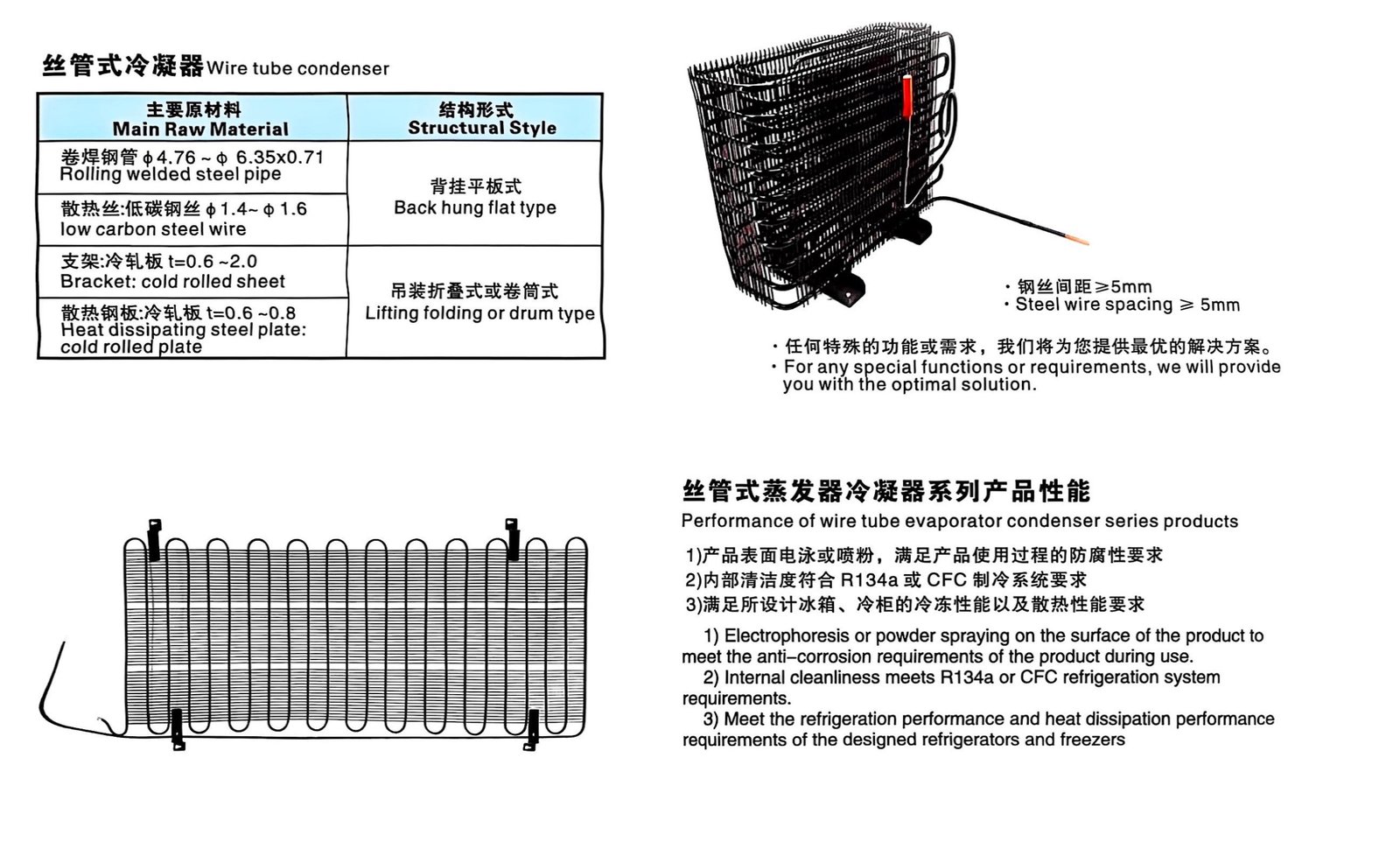

Wire tube condenser

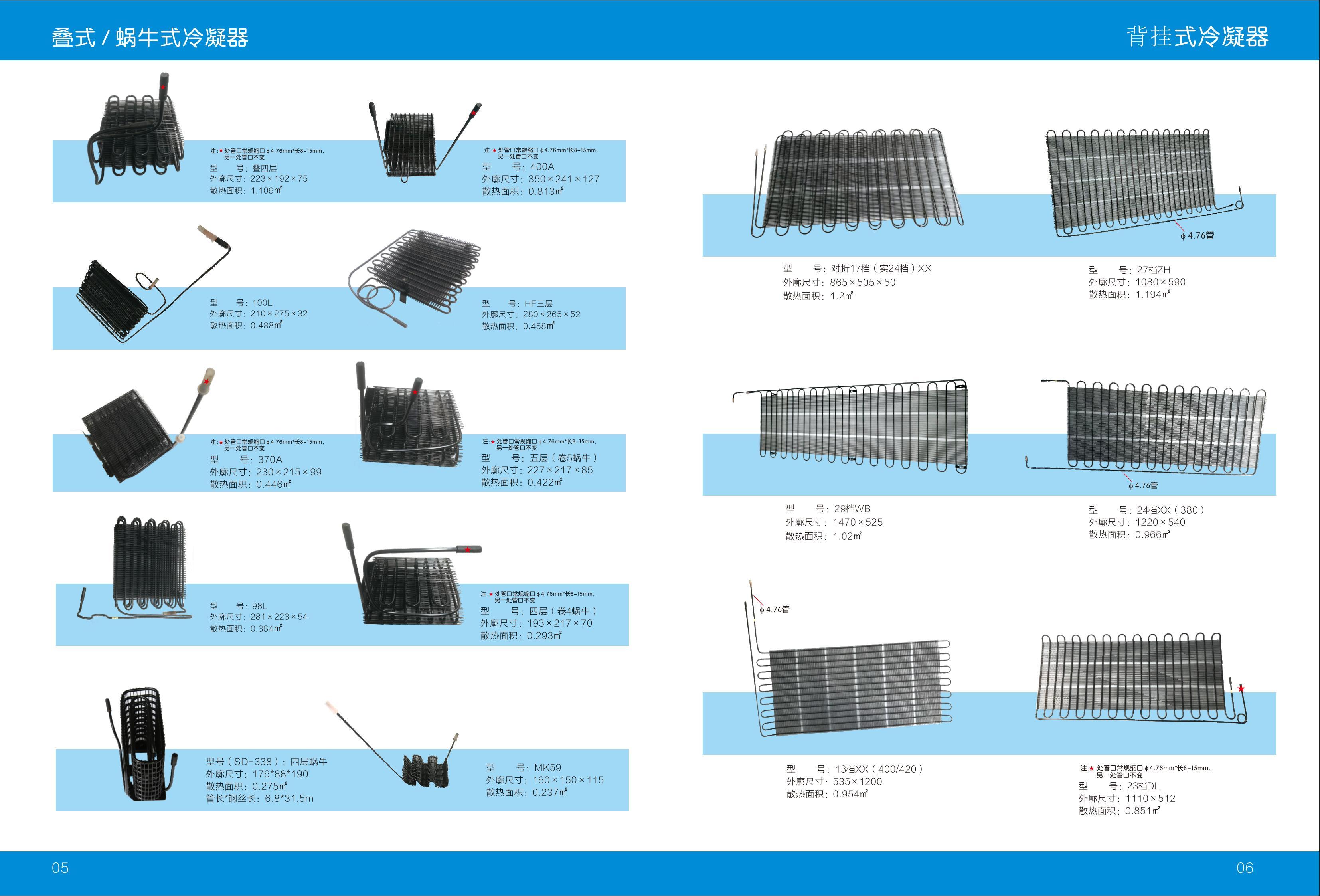

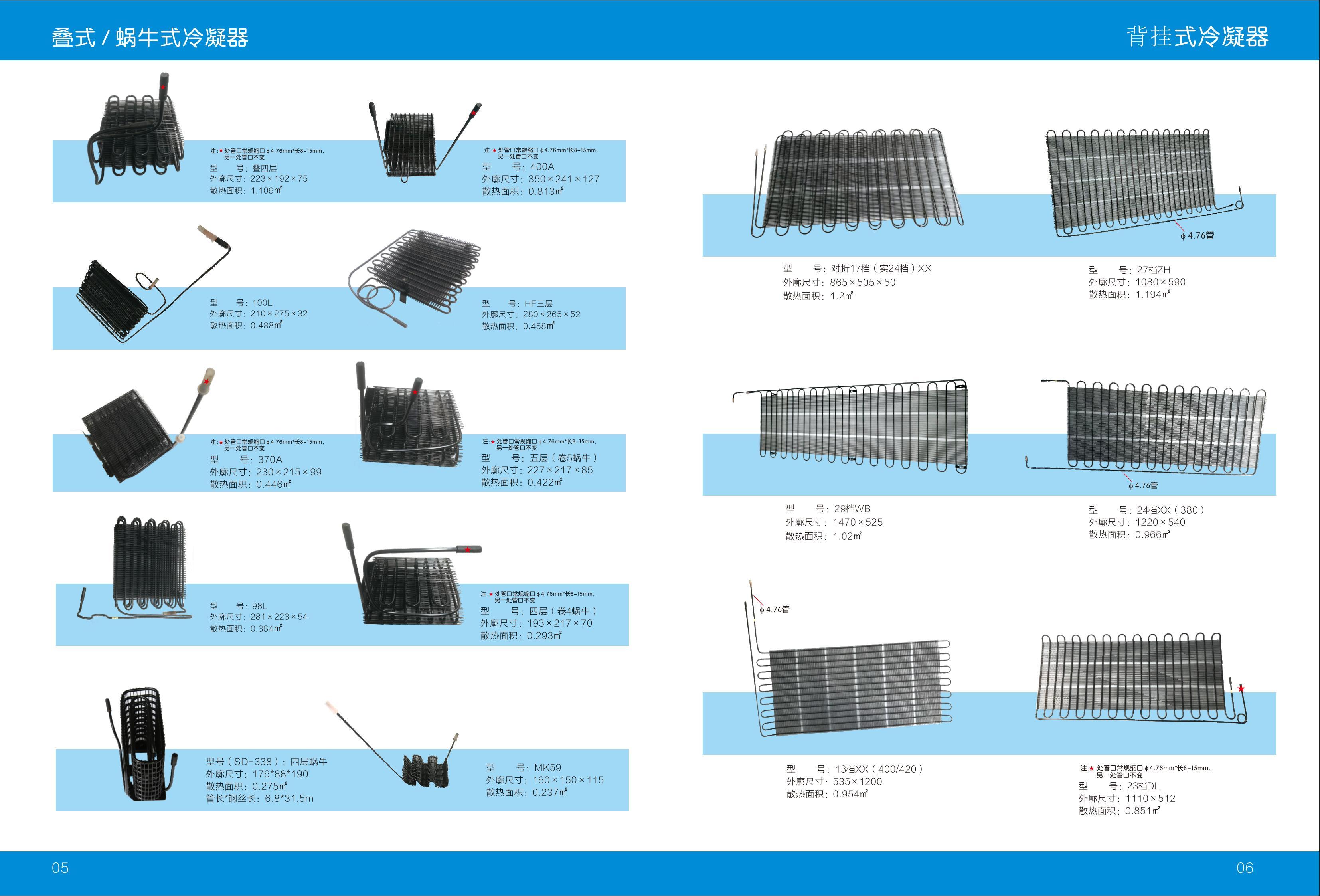

The wire tube condenser is a heat dissipation device commonly used in refrigeration systems. It is composed of rolled welded steel tubes and low-carbon steel wires through welding processes to form a rolled layer or flat plate structure. The core of its design is to use the principle of natural convection or forced convection to achieve heat exchange, optimize space utilization through the rolled layer structure, and improve heat exchange efficiency.

Products Description

The wire tube condenser is a heat dissipation device commonly used in refrigeration systems. It is composed of a coiled copper tube (or copper-plated steel tube) and a low-carbon steel wire through a welding process to form a coiled or flat structure. The core of its design is to use the principle of natural convection or forced convection to achieve heat exchange, and it is mainly used in small refrigeration equipment. For example, the wire tube coiled condenser optimizes space utilization through the coiled structure and improves heat exchange efficiency.

This condenser is commonly found in the field of white household appliances, such as refrigerators and freezers. Because of its compact structure and convenient installation, it is widely used for external heat dissipation of refrigeration units. It is also called “external condenser” or “back-mounted condenser”.

– It is welded with a coiled steel tube (such as Φ4.76mm) and a low-carbon steel wire (such as Φ1.4mm), taking into account both thermal conductivity and strength.

– There are various structural forms, including flat plate, coiled layer, folding type, etc., to meet different installation space requirements.

FAQ

Q1: How is quality ensured?

A1: we have a one year quality warranty B L issue date. If the product does not work property as described, and the problem is proven to be at our fault, we will provide exchange services for the same specific item.

Q2: Do you provide OEM or ODM service?

A2: Yes. We can produce G-air standard products under customer brand or modify the products to satisfy customers personalized requirements, or work together with customer to design and produce a totally new products.

Q3: How long can I get the feedback after sending the inquiry?

A3:Usually you will get feedback within 30 minutes during the office hours and 12 hours after office hours.

Q4: How long is the production lead time?

A4: Usually the production lead time will be 20 days once order confirmed. Sometimes we have a few.

Q5: How do you make our business long-term and good relationship?

A5: We keep good quality and competitive price to ensure our customers benefit , We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Send Inquiry

You Might Also Like

-

Precision Copper Tube Fin Evaporators for Food Processing and Cold Storage

-

Copper tube aluminum fin condenser: a core component of commercial display case refrigeration systems.

-

High-efficiency and energy-saving copper tube aluminum fin evaporator, core component of commercial display case and beer cabinet refrigeration system.

-

Long-Lasting Finned heat exchangers for Dehumidification and Drying Systems

-

OEM/ODM Copper-Aluminum Fin Heat Exchangers for Diverse Industrial Applications

-

Custom Industrial Copper Tube Fin Heat Exchangers for Refrigeration & Cooling Plants